Dealing with heavy microbial contamination in a fuel system can be tricky, often requiring a multi-stepped approach that includes both biocide treatments and physical tank cleaning. When high levels of contaminants are indicated through fuel testing, a more complex approach may be required to decontaminate the system and provide an acceptable result.

Two major factors should be considered when remediating heavily contaminated fuel systems. First, heavy contamination is almost always accompanied with biofilm production. The samples in the above image were taken from the same tank at the same time. The left and center samples were removed from the bottom at each access point on the farthest end of the tank. The sample on the right was take from the middle of the tank, center fuel level. When tested, the two visually contaminated samples contained very high levels of microbial contamination. The middle fuel sample contained minimal contamination. This confirms the majority of research, biofilms and high levels of contamination are usually found in bottoms-water and interface layers on the bottom of the fuel tank.

Fuel systems contain microbes that are both suspended (planktonic) and embedded (sessile) within biofilms. Planktonic organisms are easier to kill with biocide treatments versus sessile organisms. Over time microbes form communities within biofilm layers which contain a consortium of different types of biological life all working together to colonize and protect themselves. The biofilms are usually found in the water-fuel interface layers on the bottom, sides and tops of tanks like the ones seen in the samples. They can also form in baffled areas, fuel lines and hard to reach areas of the system.

Biofilms form as microbes secrete biopolymers and biosurfactants. These slimy, mucous-like secretions effectively protect the sessile organisms. A very thin and seemingly insignificant biofilm of 1-mm on a tank wall or top is 100 times the thickness of fungi and can be up to 1000 times thicker than the longest bacteria providing a protective barrier over the microorganisms from biocide treatments or other harmful environments. While a quality biocide helps breakdown the biofilm layers, it often takes time and more than one treatment. During the breakdown process, chunks of biomass known as flocs break off. They often contain surviving colonies requiring follow-up biocide treatments and aggressive filtration or system cleaning to adequately remove them. According to ASTM D6469, “heavily contaminated systems generally require both tank and line cleaning in conjunction with biocide treatments.”

Illustration 1

Illustration 2

Illustration 3

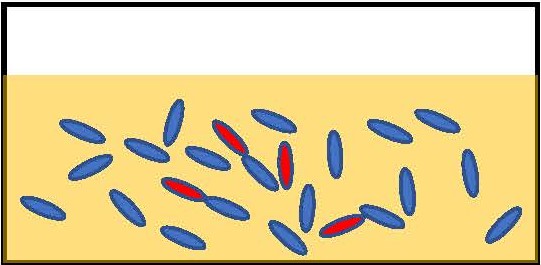

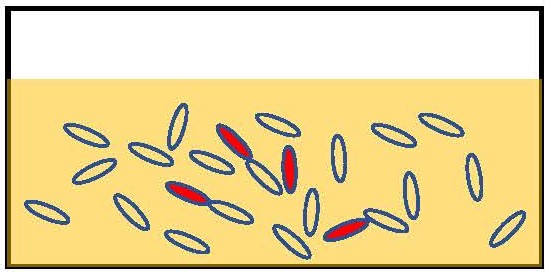

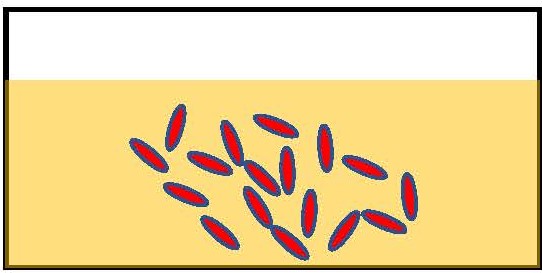

The second major factor contributing to the problem is the population profile of the microbial colonies in heavily contaminated fuel systems. Colonies contain both fast growing, dominant microbes (blue) and slower growing, subordinate microbes (red) as illustrated in Illustration 1. Dominant microbes with higher metabolic rates tend to be affected by biocides more quickly than slower growing microbes. They take in the biocide faster resulting in a quicker death (Illustration 2). With the dominant species gone, subordinate microbes with lower metabolic rates often survive and proliferate at alarming rates (Illustration 3). The metabolism of an organism governs the rate and amount of toxin taken into the organism. Slower metabolic activity is an influencing factor, often requiring a second dose of biocide to kill the remainder of microbial species in heavily contaminated systems. This is especially true if the system was initially under dosed. Thus, the importance of proper shock dosing!

It is not uncommon to see a range of microbial test results following an initial dose of biocide, including an increase in subordinate microbial colonies. Biofilms and population profile have a lot to do with the outcome of the initial dose as does the distribution of the biocide through the fuel system. That is why heavy microbial contamination levels usually require multiple biocide applications and fuel system cleaning.

4 steps to disinfecting a heavily contaminated fuel system

- Biocide the fuel system with a shock dose of Biobor®JF preferably using some method of application that will distribute the biocide adequately throughout the fuel.

- Allow the biocide time to work. Soak times need to be increased with higher levels of contamination. The longer, the better giving the biocide time to penetrate any present biofilms.

- Clean the fuel, fuel system and lines. The fuel itself should be turned over a minimum of 3 times, preferably 7 times to remove all of the flocs and dead organisms once the system has been shock treated.

- Retreat the fuel with biocide during the last phase of cleaning to ensure good mixing.

Filtration and cleaning alone are not enough to disinfect a fuel system. The only way to kill microbial contamination is to use a quality biocide. Once the system is cleaned and treated, periodic biocide treatments help to maintain the level of cleanliness. Fuel quality management includes the regular removal of free water and the use of a biocide. Biobor®JF is the original, industry standard biocide since 1965, used in the most critical application – aviation. Independently tested, EPA registered and OEM approved for use in all hydrocarbons. It does not adversely affect fuel chemistry and is more stable, less corrosive and safer to handle than other products. The Biobor® family of additives includes diesel fuel and gasoline products designed to remediate, stabilize, clean and enhance fuel. If you manage fuel and fuel systems, and are not using Biobor® additives as a way to reduce costs, downtime, liabilities and risk, contact us and learn how we can help. If you are using someone else’s products find out why you need to make the change to Biobor®. Join the Biobor®Revolution and be a part of the Biobor®Advantage.

Share the Post

Our 40 ft power boat with twin diesel tanks have black sludge and black weed like crap clogging our raycore filters, the tanks are molded in the boat with no drains, what is best to kill these microbes?

Hi Matt I have the same size boat with two diesel motors, we haven’t tested the fuel yet but I’m certain we have the same issues so wondering if you sorted your boat out yet ? And if so how ?

We have heavy contamination on the walls of the fuel tank. A lot of work to remove the tank, would like to do it in place if possible. Vertical 17 gallon tank on farm tractor. Suggestions please?

Unfortunately there are no shortcuts to cleaning a tank for removal. Many of the older systems that have been neglected or minimally maintained suffer from similar issues.