Hammonds Test, Treat, Protect FQM program starts with testing to determine fuel quality and set a baseline for further actions. In this post we will address the testing part of the program. In the next two we will discuss treatment and protection. In order to test the fuel, a cross-section of samples needs to be taken.

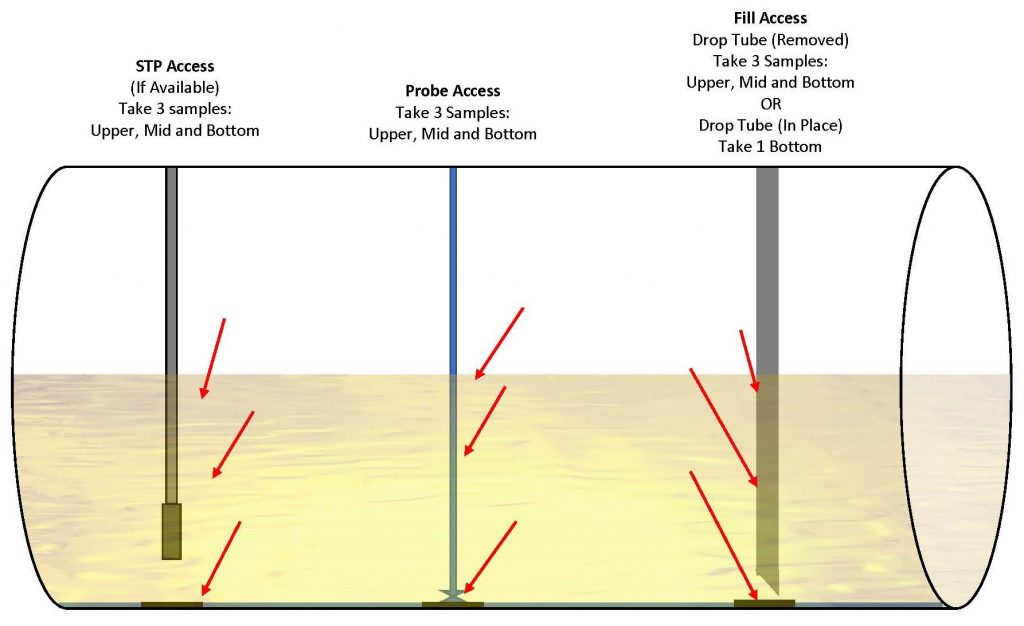

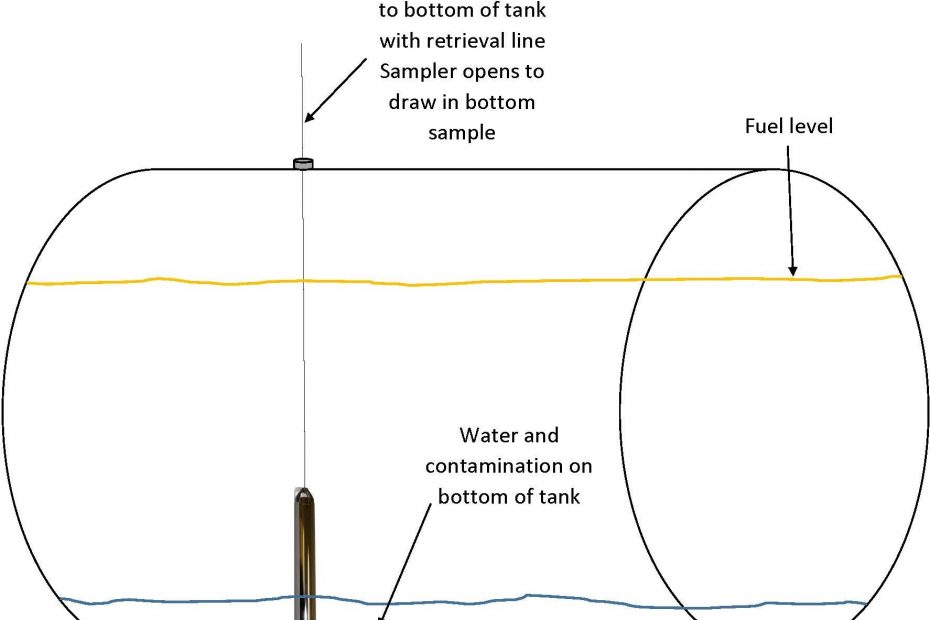

Take a cross-section of samples. Use a bacon bomb style fuel sampler. Open style dippers are inadequate for pulling acceptable samples from different fuel levels. In order to have a more complete picture of fuel quality, take several samples from different access points and different levels within the fuel. The diagram below displays several potential locations. Ideally, six to nine fuel samples are adequate to properly assess the fuel in most systems. If access is limited, as might be in a generator belly tank, take as many samples from available access points as possible as shown in the picture below.

Use clean, clear jars and fuel samplers that are presterilized. Isopropyl alcohol is a good solution to use in the field for quick clean-up and sterilization between samplings. Simply wipe the jars and sampler down with the solution prior to use and dry with a clean towel.

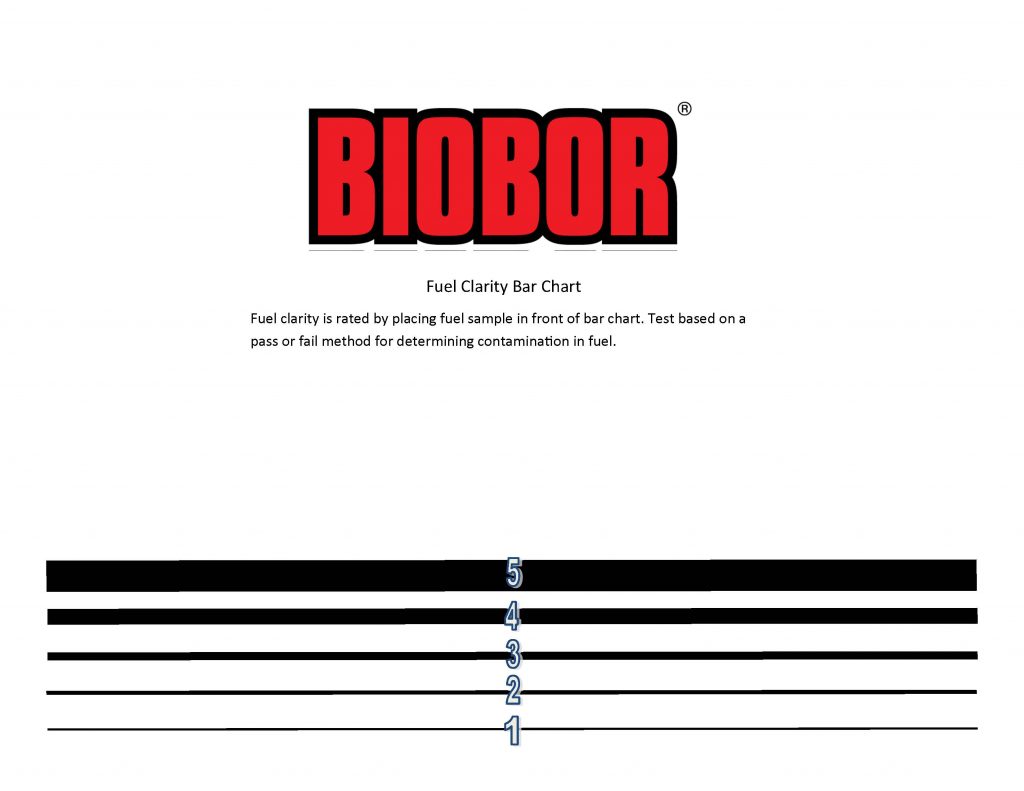

Complete a visual test using the Fuel Clarity Bar Chart like the one shown and determine the level of visual contamination. Hammonds has visual assessment guides available to help. If the sample contains biomass, water, particulates or dark aged fuel then treat and remediate the fuel. If the mid and upper layers are visually bright and clean looking, pump off the bottom contamination and treat with Biobor®JF. Clear samples may require additional testing to gain insight into problem systems.

Test the fuel for microbial contamination using the Biobor® Hum-Bug Detection®Kit or the Conidia FUELSTAT® test. Even if fuel looks bright and clear, microbial contamination is very possible. Always test the fuel.

Finally, inspect the Fuel System for Microbial Influenced Corrosion (MIC).Once the fuel assessment and microbial testing are complete, do a quick visual inspection of the fuel system looking specifically for corrosion. Corrosion is associated with microbial contamination. Contact Hammonds and ask for a copy of the Corrosion Assessment Guide to determine next steps. This is especially important if the fuel samples are clear. MIC often indicates microbial activity in difficult to sample locations within the fuel system. Follow Hammonds’ treatment instructions if MIC is identified. Remember, this is only the testing step to FQM. Next post look for the treatment.

Follow BioborShare the Post

Pingback: An Ounce of Prevention is Worth a Pound of Cure – Biobor Fuel Additives