Microbial damage to fuel systems is well documented. Corrosion, suspension of water and filter plugging are just a few of the major issues associated with microbial contamination. Maintaining a strict standard of cleanliness can hold some of the problems to a tolerable level, but not all. Good housekeeping is often not enough. In many instances, biocide treatments are necessary. In order to effectively treat a fuel system, the biocide used must be able to reach the microbes.

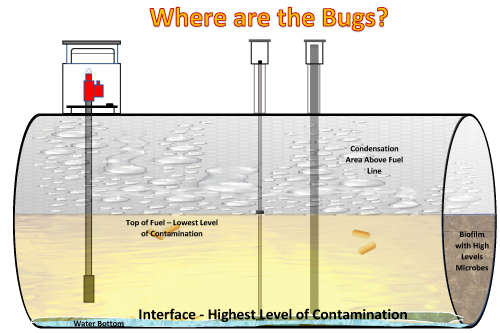

Where in a fuel tank do microbes live?

Looking at the image above, it becomes apparent that the most critical area is the interface layer where the fuel and water bottoms meet. The water bottom itself and sidewalls where biofilms can form also represent areas of high microbial contamination. The farther away from the bottom and sides of a tank, the lower the contamination level. So what is the best type of biocide to use that will effectively reach all of the areas?

There are three broad categories of biocides used in fuel systems:

- Single-phase water soluble biocides

- Single-phase fuel soluble biocides

- Dual-phase water and fuel soluble biocides

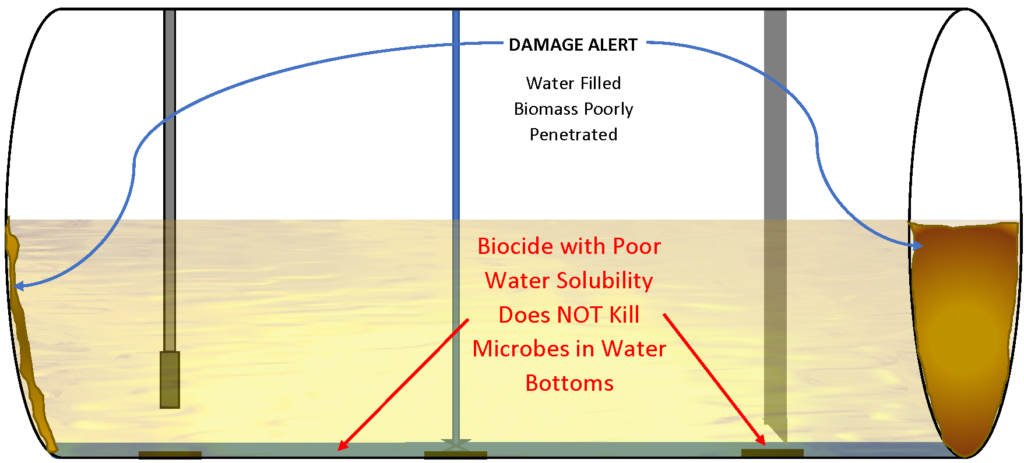

Water Soluble Biocides

Water soluble biocides are often used with the intent to sterilize water bottoms. They are not soluble in fuel. While this approach may seem like a simple solution, it is often found lacking. There are problems that arise with the use of a water soluble biocide.

- Difficulty Treating All the Water in a Tank – Tank construction often causes irregularities in the tank bottom resulting in puddles of water rather than a continuous water bottom. Tank baffles, warped tank bottoms, strike plates and tank ridges all represent areas of concern. Any impediment would make it difficult for a water soluble biocide to distribute through the system, leaving areas untreated.

- Difficulty Controlling the Proper Dose – Due to irregular shaped tanks and impediments, it is virtually impossible to determine the proper dose of water biocide. Neither over-treatment or under-treatment are acceptable.

- Incapable of Treating the Entire System – Because water biocides tend to dive through the fuel directly into the water bottom, they do not effectively kill microbial contamination in the fuel layer. They are also less effective in the fuel-water interface layer as well, where the largest level of contamination exists.

- Potentially Creates Microbial Adaptation – Adaptation is the ability of microorganisms to adapt to or adjust to new and adverse conditions. In this case, a water biocide. Studies through the years have shown that water biocides used in fuel systems are more prone to adaptation than dual-phase biocides. It has been postulated that the limited contact time as the biocide passes through the fuel layer was enough to create biocide resistance and adaptation.

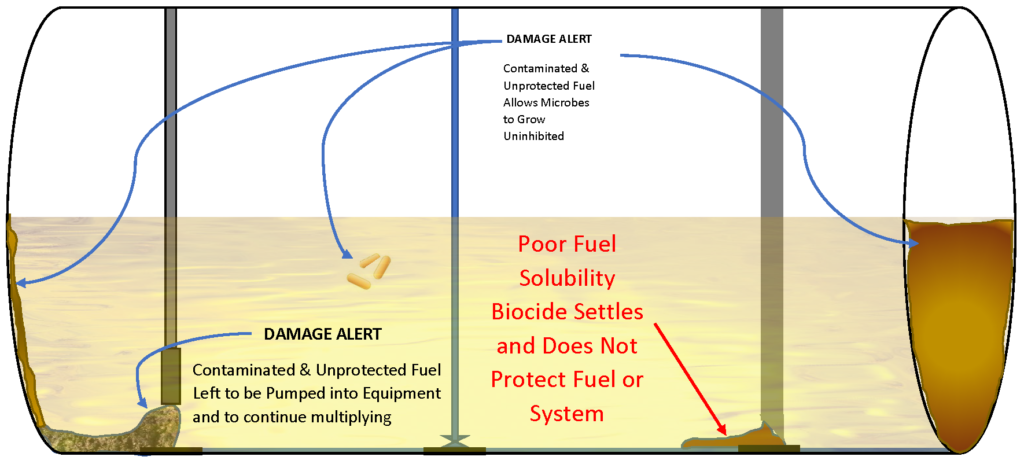

Fuel Soluble Biocides

Fuel soluble biocides are used to treat the fuel. Since they are not soluble in water, the biocide will remain in the fuel when water bottoms are drained. Like water biocides, there are problems with using a fuel soluble biocide that is not also soluble in water.

- Incapable of Treating Water Bottoms – Because fuel soluble biocides cannot solubilize in water, they are not effective at treating water bottoms. Since many fuel tanks contain pockets of water, complete removal is nearly impossible, leaving the system exposed to microbial contamination. Using a fuel biocide will not adequately protect the system.

- Incapable of Treating Entrained Water – Water molecules entrained in fuel cannot be effectively treated by a fuel soluble biocide. This presents an ever-growing problem with biodiesel that is 75% more water soluble than conventional diesel and can contain up to 10 times more water. Ethanol enriched gasoline is highly susceptible to water problems, one more reason to not use a fuel soluble biocide.

- Limited Effectiveness on Tank Wall Contamination – Any biomass on a tank wall that contains water represents a problem for fuel soluble biocides. Since the biocide cannot penetrate the water, it will not be able to kill any microbes present.

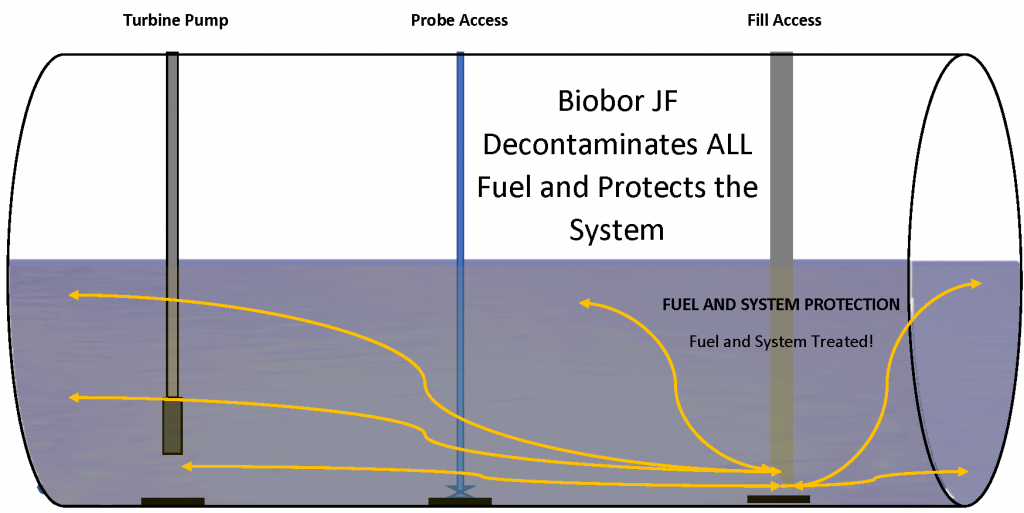

Dual-Phase Biocides

Dual-phase biocides are soluble in both fuel and water. They represent the most effective biocides for treating fuel systems, since most fuel systems contain some water. Because a dual-phase biocide can disperse into both the fuel and water layers, it can kill any microbe it comes into contact with. In contrast with the other two types of biocides, the dual-phase biocide is the only type that can protect the entire system. Biobor JF represents the best in class for dual-phase biocides. There are several advantages to using Biobor JF.

- Protects the Entire Fuel System – A biocide can only protect what it touches. A true dual-phase biocide, like Biobor JF, is designed to protect the entire system. Once added to the fuel, it will evenly distribute into the fuel. When it comes in contact with water, it partitions into the water effectively killing microbes in both the fuel and water phases.

- Protects the Equipment it is Pumped into – Biobor JF will effectively protect the entire fuel system. As the treated fuel flows through the system, Biobor JF kills any microbial contaminants it contacts along the way. Whether in fuel or water, it penetrates and kills.

- Biobor JF is the Only Biocide with Added Benefits

- Biobor JF increases fuel lubricity

- Biobor JF reduces piston ring wear by over 50%

- Biobor JF reduces sludge, sediment and water

- Biobor JF increases storage stability

Why use any other biocide than Biobor JF – protecting fuel since 1965.

Share the Post