Water and Particulate Control

In this post, we will examine the two most common fuel contaminants, particulates and water. Understanding where contaminants come from, how to limit them and what happens when we ignore them are three challenges to every fuel managers life.

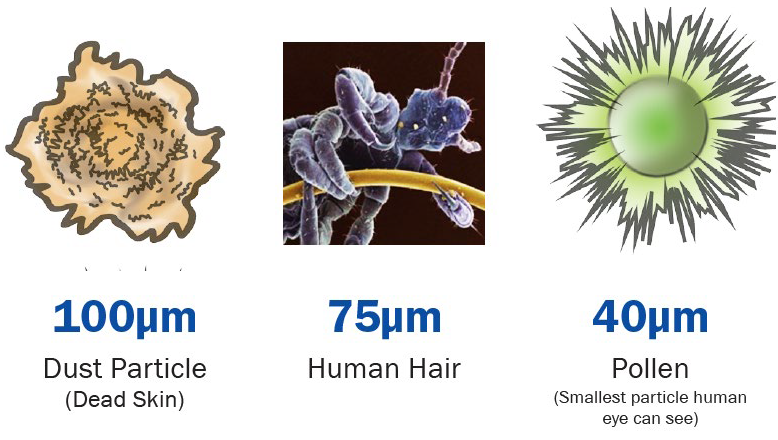

Before we get into the specific types of contamination, let’s look at at contamination size. Did you know, “SIZE MATTERS?” With contamination it certainly does. The human eye, at its best, can only see down to 40 microns (µm). Many of the contaminants are too small to see until they accumulate to form a mass in the bottom of your tank.

Water Contamination

Where Does Water Come From?

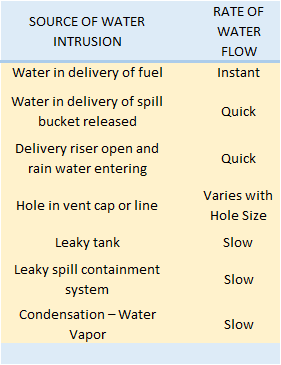

One thing is certain, all fuel contains some level of water. But where does it come from? Small amounts of water are in the fuel itself. The allowable limit is 0.05%. This is equivalent to 2.5 gallons water in 5,000 gallons of fuel. Fuel can also enter as fuel is it is being delivered. This happens during rainy season when water collects on the tank top or inside the spill bucket. When opened, the water rushes in. Water also enters poorly sealed caps, leaky tanks, risers and spill containment systems. The most common way water enters into a fuel system is through condensation. This is slow and barely noticeable until it accumulates enough to measure. The water source chart helps you to understand how quickly water accumulates depending on its source. It can be instant, noticeable or quite slow and unnoticeable until it’s too late.

How Do You Limit Water Problems?

I can answer that question in three words: sample, inspect, test. First, sample your fuel tank monthly. Second, inspect your fuel system quarterly. Third, do a line and tank test yearly. If you are sampling your fuel monthly, then the first signs of water will likely show up. In the case of a tilted tank where it may take some time for accumulated water to become accessible, quarterly inspections will help catch the problem. These inspections should include stp sumps, dispenser sumps, spill buckets and fuel system components. Look for the tell-tell signs of water – CORROSION. If you are having premature filter changes and other dispenser issues often associated with water and the microbes that grow in the water, then it is time to step into action. Test your tank and lines for tightness every year or more often if problems are suspected.

What Happens if I Ignore the Water?

It will take care of itself, right? What can really happen? You might have compliance inspections, but are they really attentive to what is going on with your system? Changes over time may not be noticeable to a once a month compliance inspector that flys in and flys out, takes a few pictures and fills out a few forms. Can you afford to ignore your system? The answer to this question is no! While compliance inspections are a part of most fuel system owner’s protocols, it is just the beginning of what really needs to be done. An intentional effort to identify changes in your system through analysis that comes from sampling, inspecting and testing. These paint a picture and tell the story of what is happening inside your tank. If you ignore it, problems will accumulate.

Particulate Contamination

Where Does Particulate Come From?

Contaminants come from many sources including product aging, the environment, microbial infection, transportation error and fuel system deficiencies. On average, a tank that receives 8,000 gallons of fuel a week can gain as much as 35 pounds of particulate contamination per year. As fuel moves in and out of a system, the tank breaths, drawing in air. Air carries with it contamination in the form of dust, microbes and water vapor. All of these accumulate in the tank, contaminating the fuel and creating problems over time. By the time the end user gets fuel, contamination levels are often high.

Settling time is a major factor with both particulates and water. The Settling Chart shows just how long it can take for some contaminants to settle out. A lot never do and are frequently pumped into equipment and vehicles, being small enough to pass through standard dispenser filtration. For certain, size does matter. It can take years for small particles to settle. Small particles will even stick to tank walls, especially when microbes are present creating an environment that captures particulate, many of which are food sources.

How Do You Limit Particulate Problems?

There are a few things that can be done to limit particulates. You could install tank vent filters to keep the tank from breathing in particulates. This would limit the additional particulates that come into the tank via respiration. However, recent studies show that the fuel being delivered to end users already contains unacceptable levels of contamination. Eventually this will accumulate. The practical answer is to clean it once a year. You can filter the fuel and sweep the bottom of the tank or do a more thorough tank cleaning. Either way, you reduce the level of accumulating particulates and as a result reduce the problems they cause.

What Happens if I Ignore the Particulates?

Like water, it will accumulate and cause serious problems. You cannot afford to let it go. What you end up with is exactly what is shown in the pictures, all actual particulate contamination removed from neglected fuel tanks.

Water and particulate contamination are a fact of life. Limiting them will save you money and system downtime. Call Hammonds Fuel Additives and ask us for help. Our experts can help you put a plan in place that makes sense. CONTACT US NOW

Follow BioborShare the Post