3 Easy Steps to Keep Your Fuel Quality in Check

Are you feelin’ lucky? When you don’t implement a fuel quality management program, luck is all you have. Keep your fuel quality in check with the Test, Treat, Protect… (TTP) approach developed by Hammonds Fuel Additives. It doesn’t take luck, just a simple and effective solution. This method involves three easy steps: fuel testing, fuel treatment, and ongoing protection through periodic inspections. By following these steps, you can ensure that your fuel remains in optimal condition and that your fuel system has fewer quality-related issues. Read on to learn more about the Test, Treat, Protect… approach and how it can help you maintain the quality of your fuel.

1. Test Your Fuel Regularly

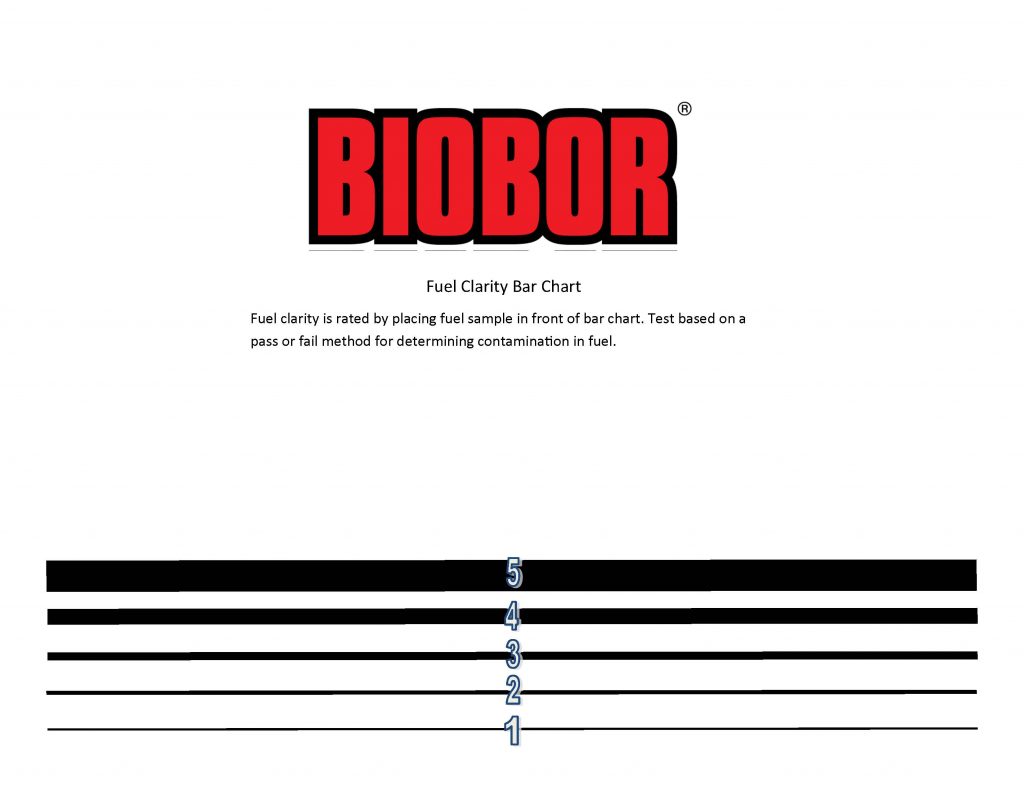

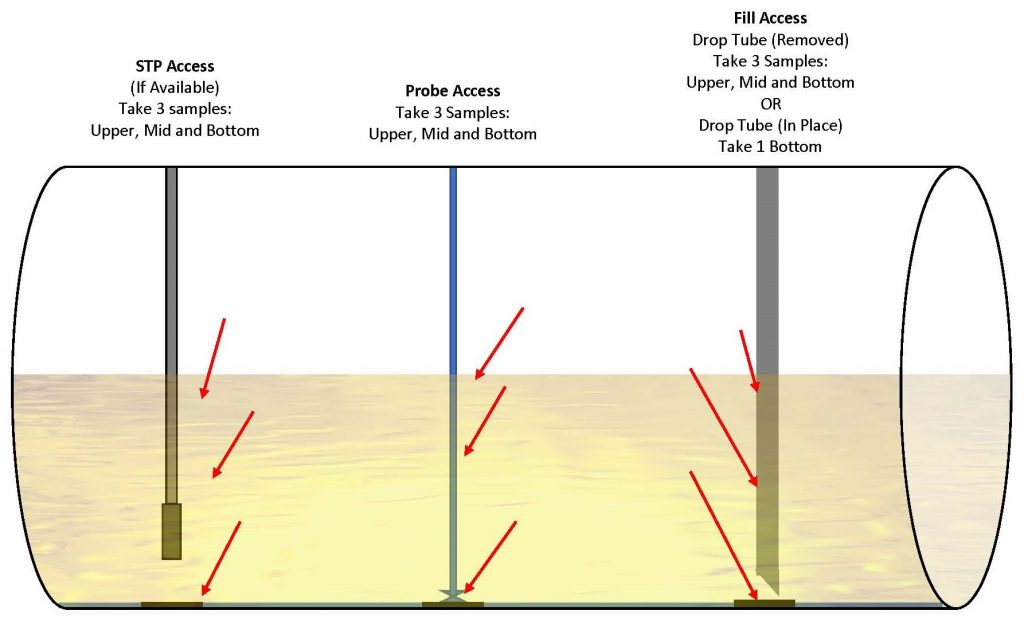

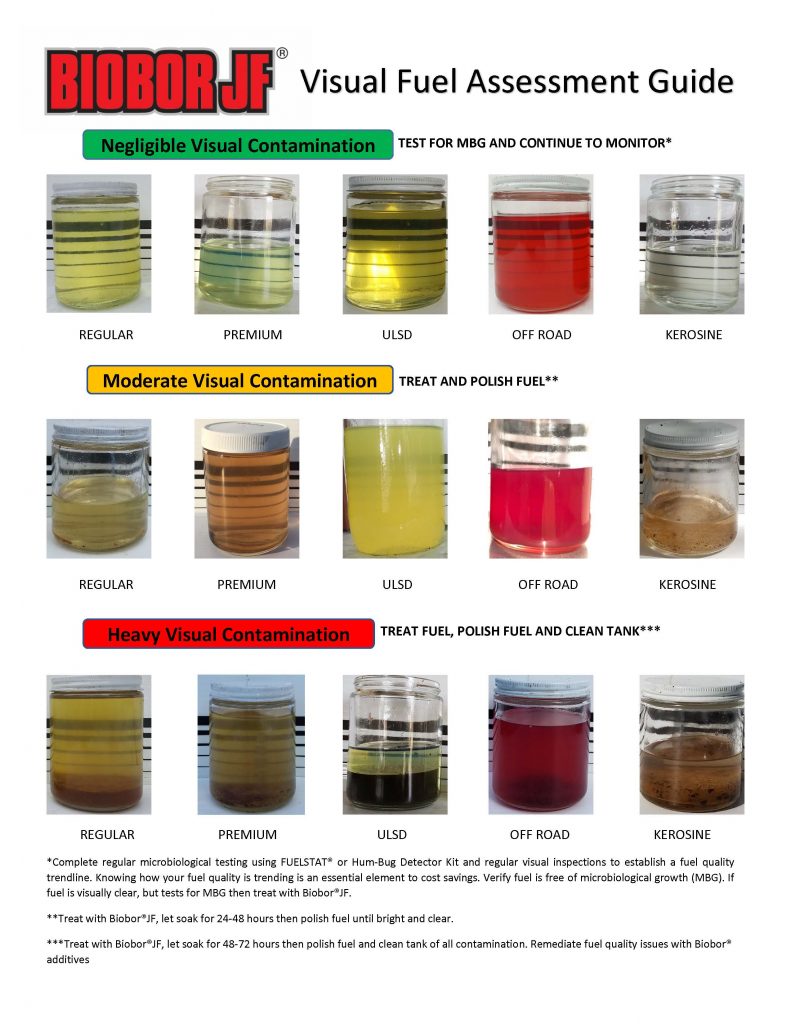

It is important to regularly sample your fuel. It’s best to take fuel samples from different access points and levels within the fuel storage tank to get a complete picture of fuel quality. We recommend taking six to nine fuel samples to ensure accuracy. When taking a fuel sample, make sure to use clean, clear jars and fuel samplers that are sterilized. After collecting the fuel samples, use a Fuel Clarity Bar Chart to determine the level of visual contamination in the fuel. If the fuel contains biomass, water, particulates, or dark-aged fuel, it should be treated and remediated.

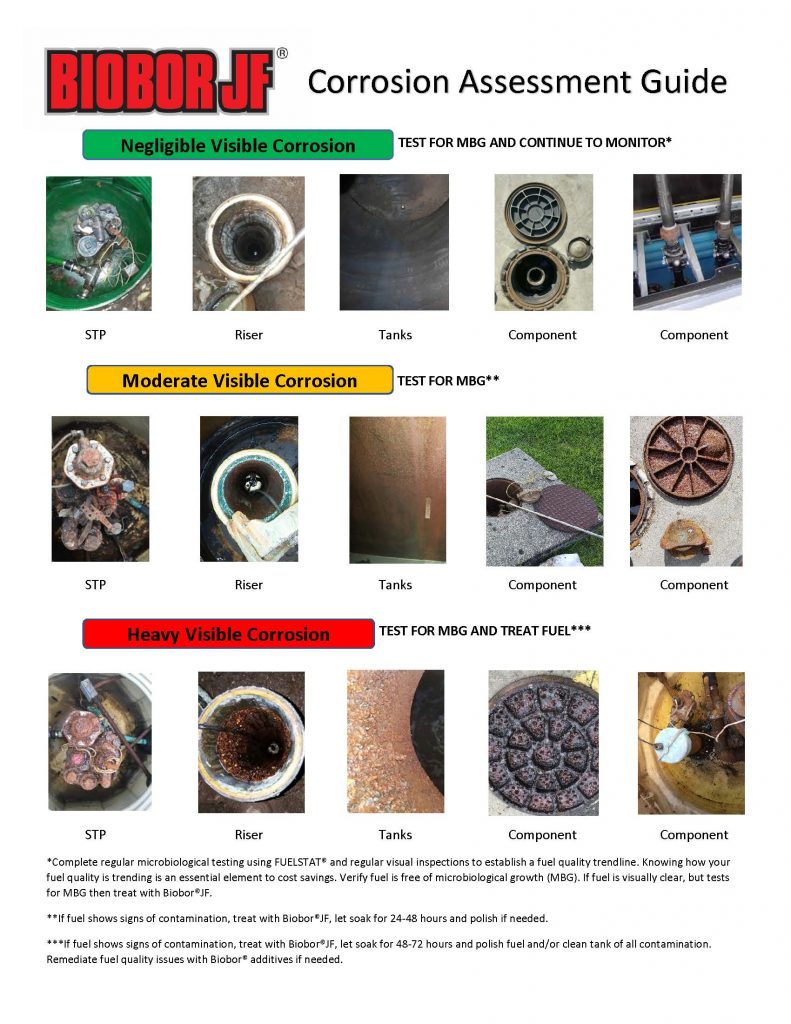

Even if the fuel looks bright and clean, it should still be tested for microbial contamination. The Biobor Hum-Bug Detection Kit or Conidia FUELSTAT test are both effective methods for testing for microbial contamination. Using Biobor JF fuel biocide and Biobor fuel additives will help protect your fuel system from microbial influenced corrosion (MIC) and other forms of fuel contamination and degradation. Testing includes regular fuel system corrosion inspections. All a part of an effective fuel quality management plan that will ensure your fuel system is properly protected. Assessment tools are available from Hammonds Fuel Additives. Contact us for more information.

2. Treat Your Fuel

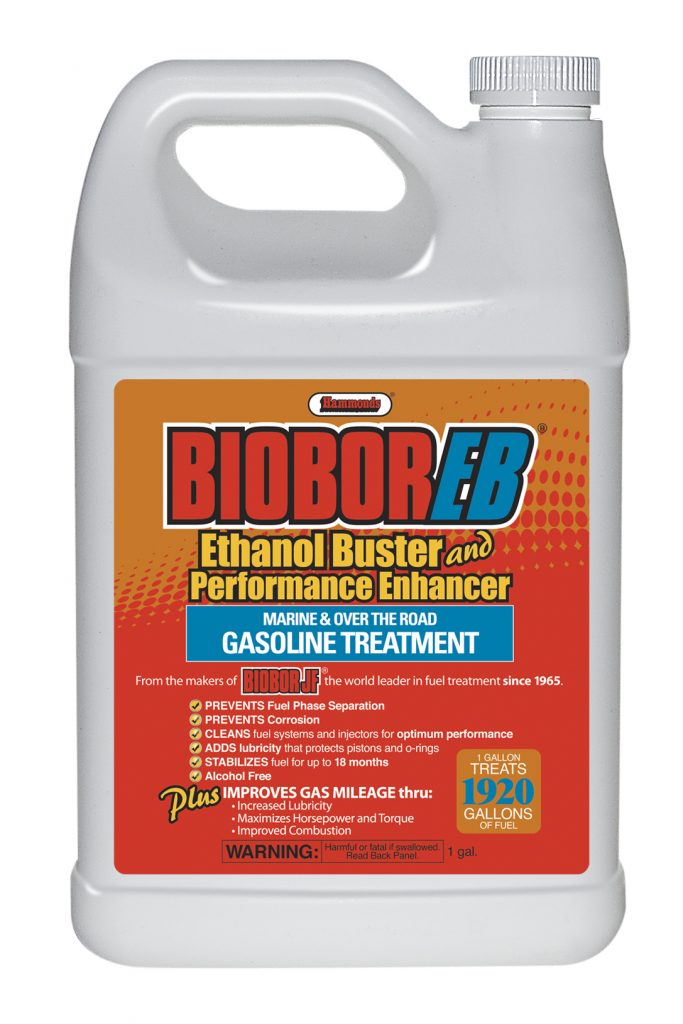

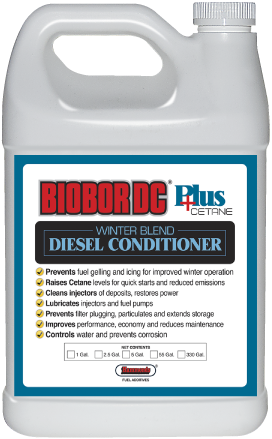

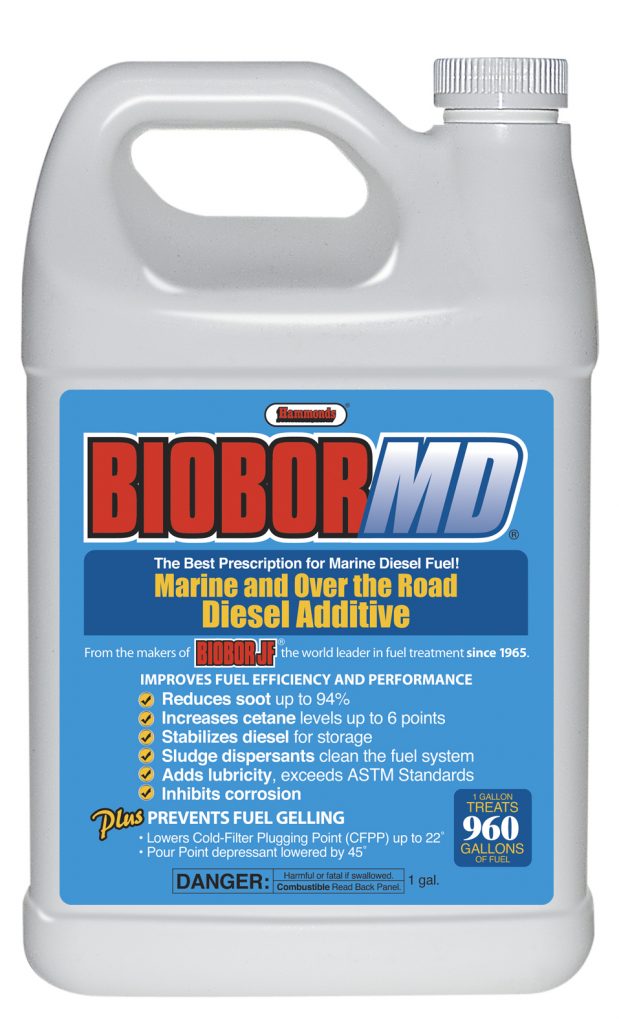

Test, Treat, Protect… is a set of practices used to ensure the quality of fuel from storage to engine. One of the key components is using the right fuel additives to remediate fuel issues such as fuel contamination, fuel degradation, and microbial influenced corrosion (MIC). Biobor JF is designed to kill microbial growth and protect the system from MIC. Use Biobor fuel additives to remediate fuel caused by oxidation and aging, as well as increase storage stability. When diesel fuel ages, it loses cetane, lubricity, essential detergents and stabilizers that need to be replaced. Both Biobor DC and Biobor MD are superior multifunctional additives that will reduce your maintenance costs and save you operational capital.

3. Protect Your Fuel System

Test, Treat, Protect… is an ongoing program designed to reduce maintenance costs, liabilities, and downtime. The goal of TTP is to protect the fuel system by ensuring fuel quality and proper storage practices. To achieve this, schedule regular inspections using the Biobor Test, Treat, Protect Field Guide. It contains several tools and instructions on how to manage your fuel. Learn when and how to use the Biobor fuel additives to treat fuel contamination and prevent fuel degradation.

If you have any questions or need help, it’s best to contact a Biobor professional for assistance. With the right fuel treatment and fuel quality management practices, you can protect your fuel system from contamination and degradation, saving you money and downtime.

Share the Post