Ethanol blended fuel seemed like a great idea. The promise of lower emissions and a viable replacement for conventional gasoline appealed to many. Today over 90% of gasoline sold contains ethanol. Unfortunately, its use has resulted in several unintended consequences, creating challenges for those who use it. In this blog, we will look at five problems created by the use of ethanol.

Ethanol is Hygroscopic

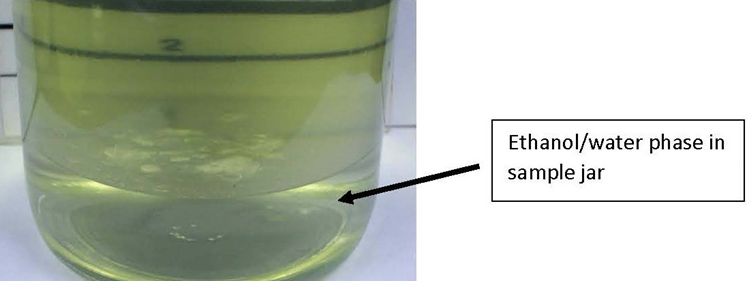

Water has always been a concern, but ethanol’s water absorbing chemistry exacerbates the problems associated with water contamination. Water is always present in fuel at some level, often suspended in the ethanol blended fuel until it becomes heavy enough to drop out. Ethanol and water are miscible, meaning they dissolve easily in each other. It is also lighter than conventional gasoline so it remains suspended in the fuel unless enough water bonds to it. Because water is heavier than fuel, it will eventually drag the ethanol to the bottom once enough is present. Research shows it only takes .398% water in fuel for phase separation to occur. At saturation the water and much of the ethanol separate from the fuel and drop to the bottom of the tank resulting in full phase separation.

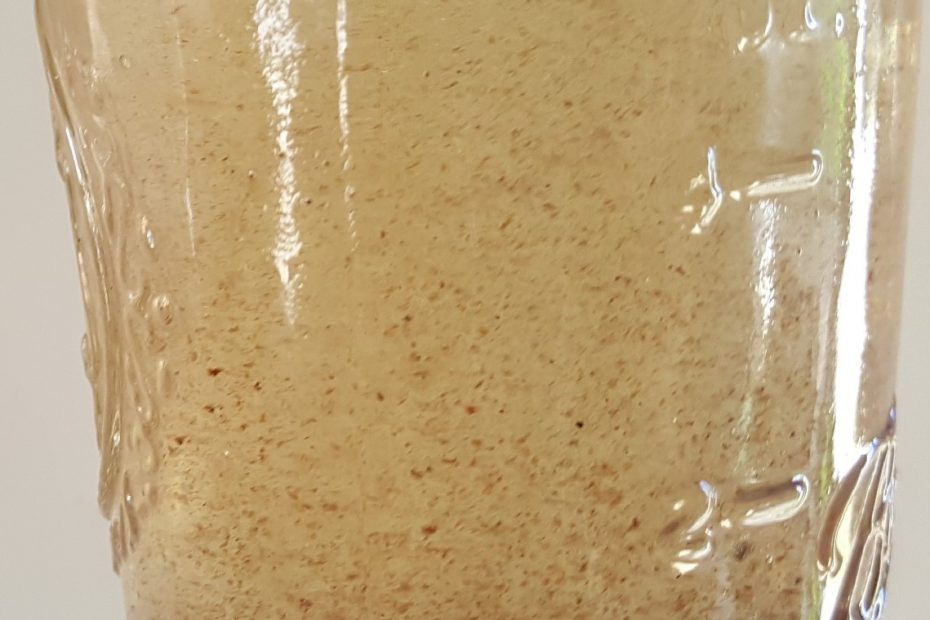

Contaminated E10 Samples

Because ethanol is used to raise octane, the fuel above the phase layer at the bottom of the tank is now substandard. Fuel can also remain partially phase separated. This happens when enough water enters the fuel but has not reached saturation. During this stage, fuel becomes hazy often clogging filters and shutting down engines. So, what can be done to alleviate phase separation? Periodic removal of water will help to reduce the possibility. The regular use of a multifunctional additive like Biobor EBthat contains a demulsifier will prevent phase separation by stopping and breaking water emulsions.

Ethanol is Corrosive

Ethanol is corrosive. Ethanol reacts naturally with oxygen in the air to form acidic compounds which lead to corrosion of fuel system components and engine wear. With the presence of both water and ethanol, corrosion is accelerated in all metal types. Aluminum engine and fuel system parts are very susceptible to ethanol corrosion. Use a corrosion inhibitor to alleviate the problems associated with ethanol corrosion. Testing shows Biobor EB to be the best choice for protecting your assets against corrosion. Accelerated corrosion testing performed on Biobor EB showed that it protects metals from corrosion, even in the most extreme circumstances. To see the independent test results, go to the Practical Sailor Article.

Ethanol Accelerates Fuel Oxidation

Fuel oxidizes over time when exposed to oxygen, becoming unstable. It loses volatility resulting in poor ignition and poor performance. Fuel volatility is crucial to combustion. It affects how easily your equipment starts, how well it runs and how efficient it operates. As fuel oxidizes, gums and varnish form, further reducing engine performance and causing engine damage. While oxidation is natural, ethanol makes matters worse. Additives can improve oxidation stability. In ideal conditions, ethanol blended fuel has a shelf-life of around 90 days. Biobor EB stabilizes fuel for up to 18 months. It protects the fuel from harmful oxidation and the effects of fuel aging.

Dirty Injector with Base Fuel

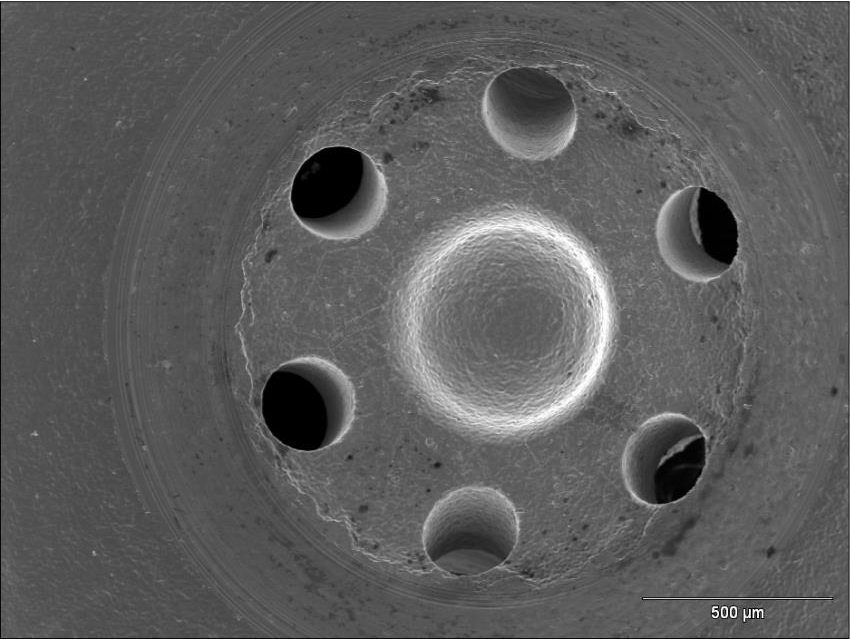

Clean Injector with Biobor EB

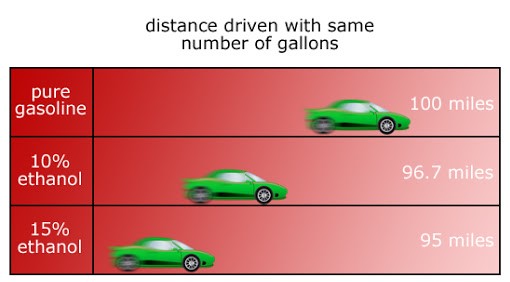

Ethanol Contains Less Energy

Ethanol blended fuel, E10, is 3% lower fuel economy, that equates to 33% less energy than conventional gasoline. Increasing ethanol from 10% to 15% or 85% will further reduce efficiency. Use Biobor EB increase performance and efficiency lost from the addition of ethanol.

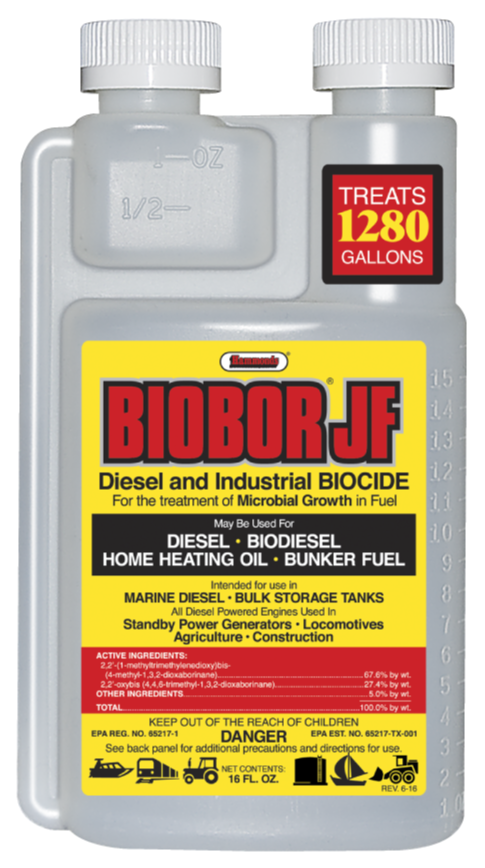

Ethanol is a Nutrient

At levels below 20%, ethanol has been found to stimulate microbial growth resulting in high acid levels and contributing to accelerated corrosion. The only remedy for microbial growth is Biobor JF, the world’s leading fuel biocide. It is also a lubricity additive, helpful in providing additional protection from the drying effect of ethanol.

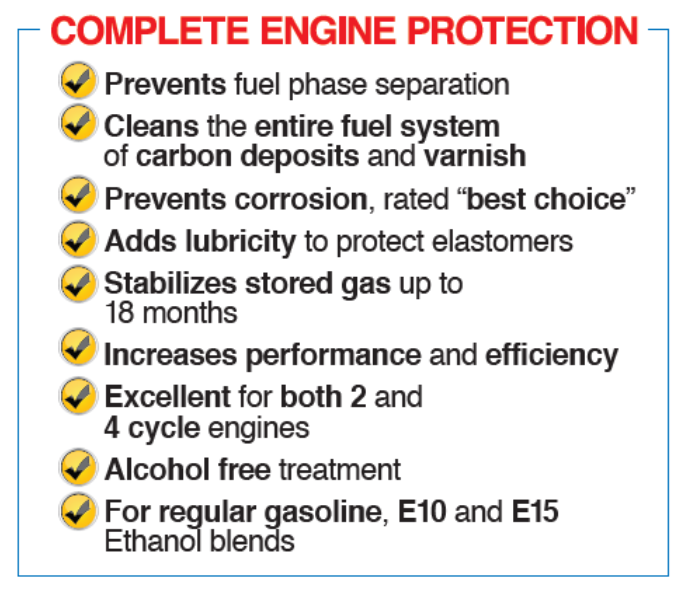

The Answer Biobor EB

Ethanol is a problem. The answer is Biobor’s Ethanol Buster and Performance Enhancer. It is a multifunctional additive that combats the harmful effects of E10 and E15 ethanol blends and increases engine efficiency. Add Biobor JF for protection against microbial contamination and that’s all you need to protect your fuel and your equipment.

Share the Post

Yes we just had to replace a carburetor in our John Deere mower (a year old) because of water condensing in the fuel! Now the company tells us to add a stabilizer treatment!

I would definitely use Biobor EB. It is an effective fuel stabilizer and if using ethanol blended fuels, it will protect the engine from ethanol related issues.