The Biobor Advantage, Part 2

The problems associated with microbial contamination in fuel continue to plague system owners. Whether in a retail fuel system, an aircraft, a generator belly tank or any other system, the problems are the same. The fact of the matter is, microbes cause serious problems. In order for fuel and fuel systems to be effectively preserved, a biocide is essential. Choosing the right biocide can be a challenge. What are the qualities of an ideal fuel biocide? Biobor®JF, was developed specifically to eliminate the problems associated with microbial contamination in fuel systems. Its design represents all of the qualities necessary to be an effective fuel biocide.

6 Attributes of an Ideal Fuel Biocide

- Solubility

- Potency

- Compatibility

- Acceptability

- Stability

- Low Toxicity

Biobor®JF’s solubility, potency, compatibility, acceptability, stability and low toxicity demonstrate its effectiveness as a fuel preservative. Choosing the ideal biocide to protect your fuel requires a balance of all six characteristics. Unfortunately, there are biocides on the market lacking one or more of these and are often mischaracterized as effective when in reality, they may not provide effective protection for your fuel system.

Solubility

Biobor®JF is soluble in both fuel and water phase. It is miscible (100% soluble) in all proportions in fuel and is designed to effectively partition between both fuel and water phases found in fuel systems. All systems contain some level of water. Bacteria and fungi require water to survive and primarily make their home in the water-fuel interface layers found on tank bottoms and walls where free water and condensation form. As a result, it is imperative to have a biocide that is very fuel soluble, yet effectively partitions and distributes between the two immiscible phases to provide sterilization in both layers. In the presence of water, Biobor®JF partitions into water, effecting a microbial kill in both phases. The chemistry demonstrates its hydrolytic stability, effectiveness and solubility even when field conditions are not ideal. Studies show when Biobor®JF enters water, it does not lose its efficacy because it is precisely designed for such an action.

How does solubility relate to efficacy and why is it important? If a biocide cannot fully solubilize, then it will have limited efficacy. It will not be able to protect the fuel and fuel system adequately, leaving areas of the system unprotected. A biocide that is not fully fuel soluble cannot flow along with the fuel and reach all areas of the fuel system to adequately protect it. Water gets trapped, accumulating along baffles and inaccessible low-lying areas of the fuel system, allowing microbial growth to take place. A biocide that has poor fuel solubility will not be able to reach those areas and will ultimately fail to decontaminate the entire system. Fuel solubility is essential. Effective partitioning from fuel to water is also vital. Biobor®JF was designed to do both, effectively protecting the entire system where ever the fuel flows, and delivering adequate active ingredient to water bottoms for an effective kill. Because of its solubility, it is suitable for batch blending, injection and splash blending, evenly distributing throughout the fuel in the tank.

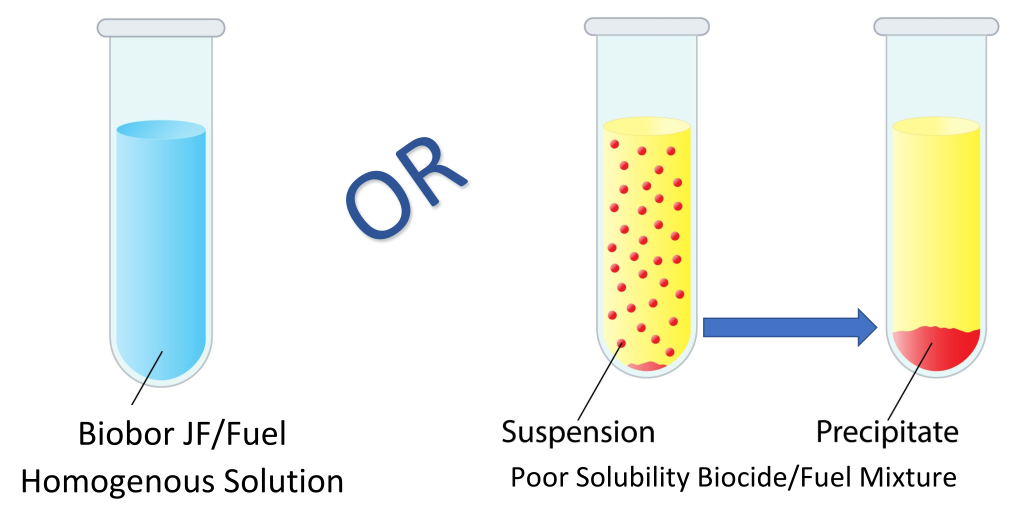

A miscible biocide like Biobor®JF will form a homogenous solution with the fuel. In comparison, an insoluble or poorly soluble biocide will form a temporary suspension, ultimately ending in precipitation. The image represents the choices, a homogenous solution or a heterogenous mixture that will precipitate and stratify. Now picture this occurring, an acidic biocide settling out into a small area of your fuel system.

Potency

Finding the ideal biocide that is effective in your fuel system and has the other necessary attributes can be challenging. Biobor®JF has a long history of controlling microbiological growth in all hydrocarbons. Through the years, its effective biological control has been tested and proven. Third party laboratory and field tests consistently demonstrate the efficacy of Biobor®JF over a variety of fuel types and contamination levels. Biobor®JF is effective even in low doses. At the curative dose rate, it works effectively for both short and long-term protection. The potency of a fuel biocide is not only measured through efficacy (ability to kill the microbes infecting your fuel system) but also by other factors. It should not be susceptible to adaptation. It must not be a nutrient source for microbes and should be able to penetrate layers of biomass to make an effective microbial kill.

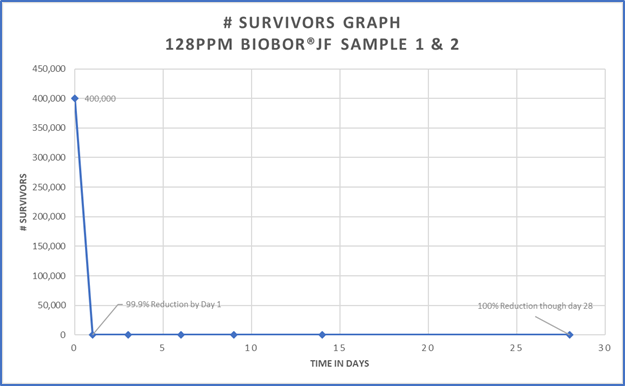

Biocides can be susceptible to adaptation. Biobor®JF is not. From early testing to the present, there is no evidence that any microbes common to fuel contamination have ever adapted or reduced its efficacy. Improper application and sub-lethal doses have been known to cause microorganisms to adapt to other biocides. Studies on Biobor®JF have been completed using what was previously believed to be sub-lethal doses as low as 100ppm. No microorganisms were found to have adapted to the biocide. In fact, over time even low doses of Biobor®JF proved to be effective at sterilizing the fuel. The graph is just one illustration showing the efficacy of Biobor®JF even at doses below the recommended treat rate. In contrast, adaptation and further microbial proliferation has been recorded with other fuel biocides.

A biocide should not act as a nutrient source for microbes. Sub-lethal doses also can become nutrient sources for microbes. This often happens in two ways. The first is when a system is under-dosed. With the exception of Biobor®JF, under-dosing has been shown in other biocides to be a serious mistake, allowing for both adaptation and the biocide being used as a nutrient source. The second happens when a biocide does not blend well with the fuel. As previously mentioned, poor solubility is related to a biocide’s potency. A biocide with limited fuel solubility will not reach all areas of a fuel system. It will settle out and create areas in the system that either has sub-lethal levels or none at all. This will allow for microbes to use the biocide as a food source, potential adaptation and further microbial proliferation. Another reason why a highly soluble biocide should be used. Some biocides contain microbial nutrients like sulfur and nitrogen. These biocides are more susceptible to becoming a nutrient source. So, sub-lethal dosing, improper blending and nutrient ingredients all affect the potency of a biocide. Biobor®JF overcomes all of these.

Microbes will create their own environments. They release enzymes, surfactants and acids. They break down the fuel and fuel system materials. What results over time is biomass films and enzymatic slime. One significant difference between Biobor®JF and other biocides is its effective penetration of films, slimes and biomass associated with microbial contamination. Microbial enzymatic biolayers make it difficult for biocides to penetrate and kill bacteria or fungi. Testing shows Biobor®JF effective at penetrating these layers and preventing their formation.

Before

After

The pictures of a marine vessel fuel purifier from a field study show the before and after effects of using Biobor®JF. The biocide effectively prevented the biomass build-up. Studies also show the effective long-term sterilization of fuel systems containing water contamination. Biobor®JF is proven through efficacy studies to be a potent and effective sterilizer. A shock dose is most effective, sterilizing fuel and providing fuel system protection.

Compatibility

The ideal biocide should have no adverse effect on fuel specifications or system components. Biobor®JF was extensively tested and used for over five decades with no known deleterious effects. Rigorous testing performed and continued use over 56 years confirm its compatibility. Biobor®JF is compatible with common fuel system materials. A battery of tests on common materials used in engines, fuel systems and equipment concluded broad compatibility. Soak tests at elevated temperature were performed on metals, sealants, coatings and gaskets. Critical parameters were measured during testing with positive results. Fuel biocides are known to be corrosive. In contrast, according to NACE Standard testing, Biobor®JF is classified a non-corrosive material, one additional point of differentiation.

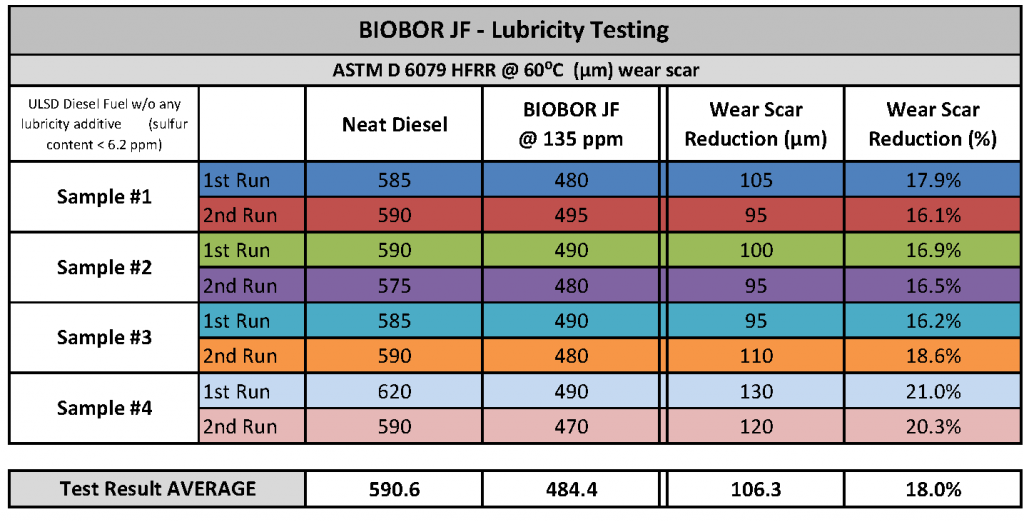

Numerous engine hours were accumulated on fuel containing Biobor®JF including overdosing showing no adverse effect on engine components. No harmful effects on engine performance were noted during rig testing or in field. It should also be noted that Biobor®JF adds lubricity, reducing wear scar tendency by almost 20%, resulting in lower maintenance costs and better engine performance. It is the only fuel biocide to be a lubricity additive. While other biocides are acidic and corrosive, Biobor®JF is non-corrosive and lubricating, a major advantage over all others.

Acceptability

Since 1965, Biobor®JF has earned an exhaustive list of recommendations, approvals and certifications that continues to grow. Diesel engine, turbine engine and airframe OEMs recommend Biobor®JF. Fuel users across the globe use and recommend it. Biobor®JF is mentioned specifically in numerous operation manuals for solving fuel contamination issues and is the only biocide available and approved for use in aviation jet fuel. Biobor®JF has a pedigree like no other. There is a reason no other fuel biocide is mentioned in so many equipment manuals and recommended by equipment manufacturers.

Stability

The chemistry of Biobor®JF demonstrates its hydrolytic stability, effectiveness and solubility even when field conditions are not ideal. Studies demonstrate its stability, remaining in solution, not settling or stratifying even under the less than desirable conditions of long-term storage. It is essential to use a biocide that is capable of protecting the fuel for both short and long-term storage. Some biocides are not suitable for long-term storage protection due to various instabilities. Already discussed, fuel insolubility resulting in precipitation is a major instability issue with other biocides. Temperature and pH can also affect a fuel biocide’s stability and effectiveness.

Biobor®JF is stabile even under some of the more extreme temperature vacillations. It has a wide range of temperature applications. Its chemistry is known to have deicing characteristics, another advantage over other biocides. Freeze point is another important factor to consider. Some biocides freeze at temperatures as high as 50°F, limiting application and solubility under those conditions. Some biocides are affected by high temperatures. Storing in a maintenance shed or trailer may provide enough heat to deactivate other biocides. In less than ideal storage conditions, Biobor®JF will not deactivate or become unstable like others do. Both high and low temperatures can have a negative effect and temperature stability is a key element. Biobor®JF’s stability offers a wide range of conditions to which it can be applied.

Another significant factor is pH. Biocides can be deactivated in different ranges of pH. Some are sensitive enough to be negatively affected by the environments created by microbial contamination, reducing the biocide’s efficacy. Biobor®JF is not affected by pH. It remains stable in the range of fuel system environments.

Low Toxicity

Biocides can be dangerous and difficult to handle. Common fuel biocides contain potentially dangerous chemical mixtures including thiocyanates or isothiazolines. Like most, they are highly toxic, acidic and corrosive making them difficult to handle. Handling requirements often include special personal protection equipment like respirators. In contrast, Biobor®JF is a non-corrosive, low-toxic biocide requiring normal handling precautions. Its boron chemistry means low-toxicity to mammals. Recent studies indicate boron is a beneficial pharmaceutical, attributed to bone health, having both antiviral and antibiotic properties. Biocides that require special handling because of their undesirable characteristics, make them more difficult, costly and riskier to apply.

Biobor JF is the Biobor Advantage

In summary, microbial growth will occur in fuel systems with or without the presence of visible water. Microbes are everywhere. Eliminating free water is part of the solution. Good housekeeping is always a first line of defense against serious microbial contamination. However, the effective use of a biocide is the rest of the solution. The most challenging part is finding the right biocide, the ideal biocide. Finding a biocide that has excellent fuel solubility, potency, compatibility, acceptability, stability and low toxicity is the key. Biobor®JF is effective at controlling microbiological growth in hydrocarbons both short and long-term because it exhibits these qualities. Through laboratory experiments, field studies and decades of successful use, Biobor®JF has been found to be the ideal biocide.

Follow BioborShare the Post

Pingback: Dealing with Deceptive Business Practices – Biobor Fuel Additives