Lubricity

Lubricity additives are used in diesel fuel to help reduce engine component wear and prevent unnecessary damage due to poor lubrication. Today’s diesel fuels are dryer and contain less friction reducing lubricant than fuels pre-2006 when the low sulfur mandates came into effect. The mandates required the removal of sulfur down to 15 parts per million (ppm). This is accomplished through hydrodesulfurization (HDS). HDS involves exposing the hydrocarbon to high temperature, high pressure and hydrogen that results in removing the sulfur and producing a ultra low sulfur diesel fuel among other products. One of the consequences of HDS is the negative effect it has on fuel lubricity. Diesel fuel lubricity is much lower, often lower than the required standard which requires lubricity improvers to meet the standard.

How is lubricity tested and what is the standard for diesel fuel?

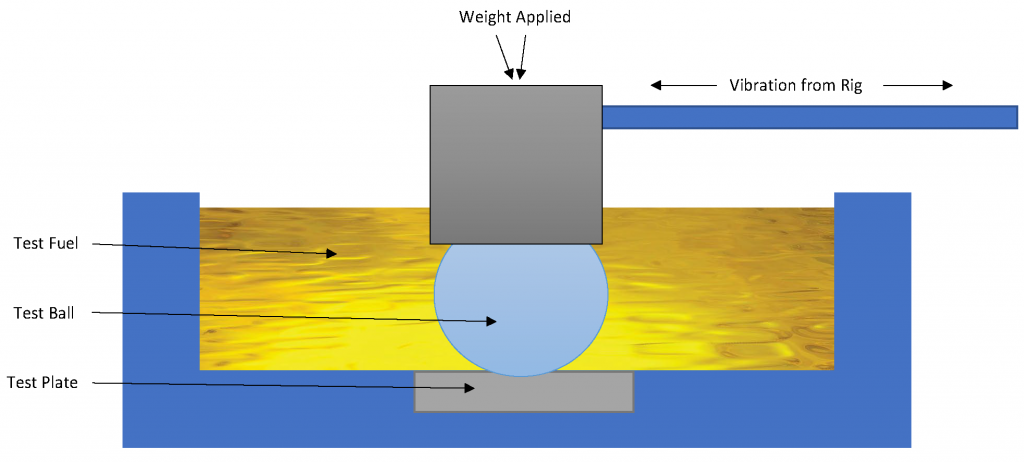

The ASTM test to determine lubricity, D6079 is done on a High Frequency Reciprocating Rig (HFRR). Diesel fuel is placed in the test rig that is designed to simulate engine component movement and wear. Test results quantify the fuel’s ability to resist friction. The simple diagram shows an HFRR. Once the test is complete on the rig, wear scar on the test plate is measured.

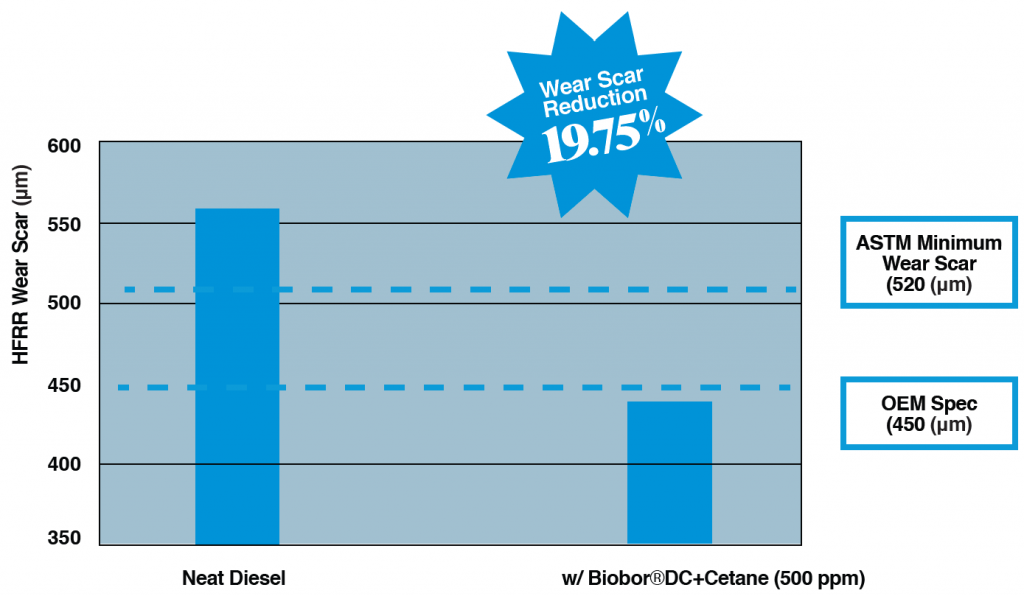

Wear scar is measured in microns (µm). ASTM D975 is the standard specification for diesel fuel. It states that diesel fuel must meet a lubricity specification or wear scar of 520µm or less. Today it is not uncommon to see Ultra Low Sulfur Diesel (ULSD) leave the refinery with a wear scar of 600µm or more. The Original Equipment Manufacturers (OEM) suggest a maximum lubricity of 450µm.

What can be done to meet the lubricity standard?

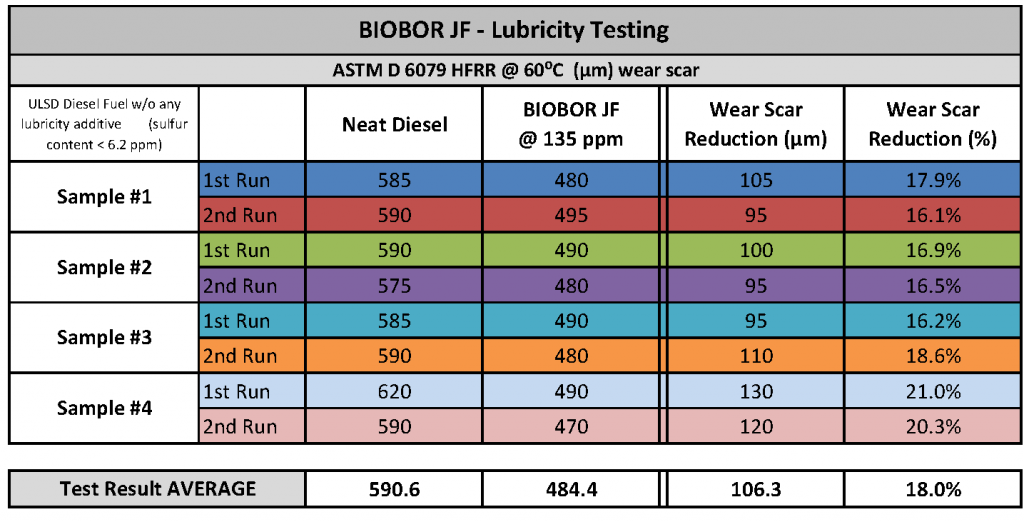

The only way to increase the lubricity characteristics of ULSD is to use an additive. For Biobor users, that can be done a couple of ways. If you are already using Biobor JF microbiocide for microbial contamination, then you also get the added benefit of a quality lubricity additive. Biobor JF is more than a biocide. It is a lubricity additive. Check out the results.

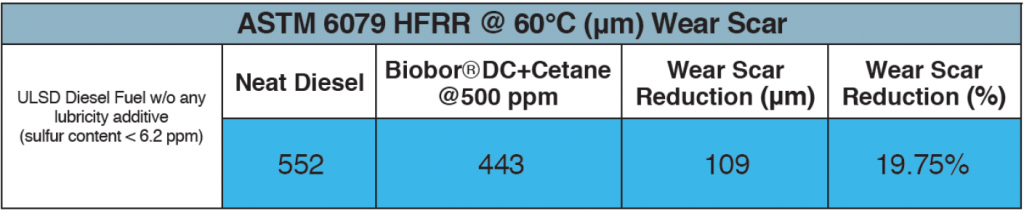

The other way is to use Biobor DC+Cetane. It contains a lubricity additive that will provide the necessary lubricity protection needed for everyday use as well as long-term storage.

Share the Post

Which additive products add the most lubricity? And are available for purchase?

Both Biobor JF and Biobor DC offer about the same lubricity factor. It depends on what you are looking for. If you are looking for a multi-functional additive that offers additional benefits Biobor DC is a great option. It is designed to enhance the stability, operability and performance of ultra-low sulfur diesel fuel. If you need a fuel biocide that eliminates and prevents microbial growth in fuel and dramatically increases the life of engine filters, then Biobor JF is the best. Also note, that both Biobor DC and Biobor JF can be used together for optimal performance. To purchase go to our website at https://www.biobor.com/where-to-buy/ to find it online or find a local store.