There is nothing worse than starting your furnace and realizing it doesn’t work. Microbial contamination of fuel is linked to equipment failure. System owners may service their heater seasonally, but often neglect basic housekeeping which includes fuel quality management. So, fuel related issues prevail. In this post, we will investigate fuel related problems, the answer to those problems and the results obtained by implementing the answer.

The Problem

Today’s heating oil has a short shelf-life. Extreme weather exposure shortens it even more. While most homeowners have some fuel left at the end of each season which is not typically used until winter rolls back around, it is not uncommon to hear of some storing fuel for as much as two years. The longer fuel is stored, the more potential for fuel related problems. That is why fuel needs to be managed. Taking care of the fuel and fuel system are just as important as having your unit serviced on a regular basis.

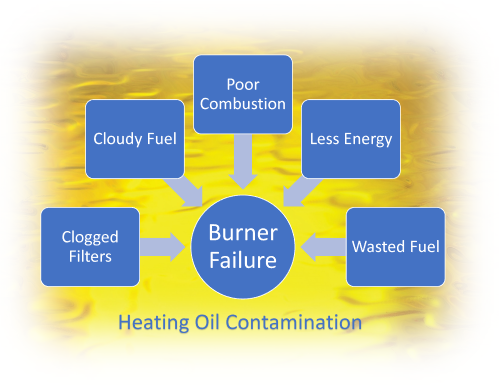

Microbial contamination represents a real challenge to maintaining fuel. The presence of living microbes in your fuel and fuel system is almost guaranteed. While the level of contamination is a variable, one thing is certain, microbes – both bacteria and fungus – create sludge, biomass and acids in the fuel. That is why it is important to know how that can affect your system. Some of the more common problems related to microbial contamination are:

- Plugged nozzles, fuel filters, oil lines and valves are often associated with microbiological growth in fuel. As microbes grow in the fuel, they produce biomass in the form of slime, sludge and sediment that attaches to the system and floats in the fuel. Water present in the fuel tank results in more severe incidents of biomass. These microbial byproducts will clog the system, causing damage and blocking the proper flow of fuel to your furnace. This can result in a system failure or lower system efficiency. That means less heat or worse, no heat at all.

- Heat exchanger failure can occur. The heat exchanger is the main part of the furnace that heats up the air. It is made of coils that absorb and transfer heat. Microbial contamination will eventually cause combustion problems. Lower combustion equals less energy output and less heat as a result. When this happens, the metal coils expand and contract eventually causing cracks. This can be a very serious health hazard because it will allow carbon monoxide and other gaseous poisons from the combustion process to seep into the home.

- System corrosion is often associated with microbial contamination. Microbes are known to produce acids. As they eat the fuel, acids are produced and released into the system causing microbial influenced corrosion or MIC. These acids result in accelerated corrosion everywhere the fuel flows or anywhere the microbes are present. Condensation is a common occurrence in fuel systems. As the tank breaths, condensation forms on the top, sides and bottom of the tank. This becomes a breeding ground for microbes, multiplying the problem with MIC.

This certainly is not all of the problems associated with microbial contamination in heating oil. Though it does represent a few of the major issues. The presence of microorganisms throughout fuel systems is well documented. What is the answer to limiting their effect in heating oil systems?

Biobor JF Prevents Microbial Contamination

The Solution

The solution is two-fold. Most microbes need water present to survive. However, microbial growth will occur in fuel systems with or without the presence of visible water. It is important to remember, microbes are everywhere and water is always present at some level. Many microbes are essential to life and do not hurt us. There are about 100 different microbes commonly found in fuel that are harmful to fuel systems. Many of them require some amount of water to survive. So, eliminating free water is part of the solution. Good housekeeping is always a first line of defense against microbial contamination. Check for the presence of water in your fuel system. If it is present, remove it.

Once water is minimized, the use of a biocide is the rest of the solution. Fuel biocides are chemical additives used to control and prevent microbial contamination. They are specifically designed to inhibit the growth and activity of microorganisms. Biobor JF has been the most widely used fuel biocide on the market. Recommended by numerous equipment manufacturers, Biobor JF eliminates and prevents microbial growth in fuel, preventing corrosion and extending the life of your equipment. It targets and eliminates microbes, preventing their proliferation and the associated problems they cause in home heating fuel. Biobor JF helps prevent the formation of biofilms in fuel systems that lead to clogged fuel filters, corrosion, and fuel flow issues. By inhibiting biofilm formation, it helps maintain the cleanliness and efficiency of your furnace. Because Biobor JF works in both fuel and water phases, it effectively controls microbial contamination even when hard to find water is present.

The Result

Through laboratory experiments, field studies and decades of successful use, Biobor JF has been found to be the ideal biocide. The results are difficult to dispute. Since 1965, it has been studied and tested for its effectiveness against microbial contamination. (Study References) The following laboratory study, field studies and customer reviews show the effective results of using Biobor JF.

Laboratory Study

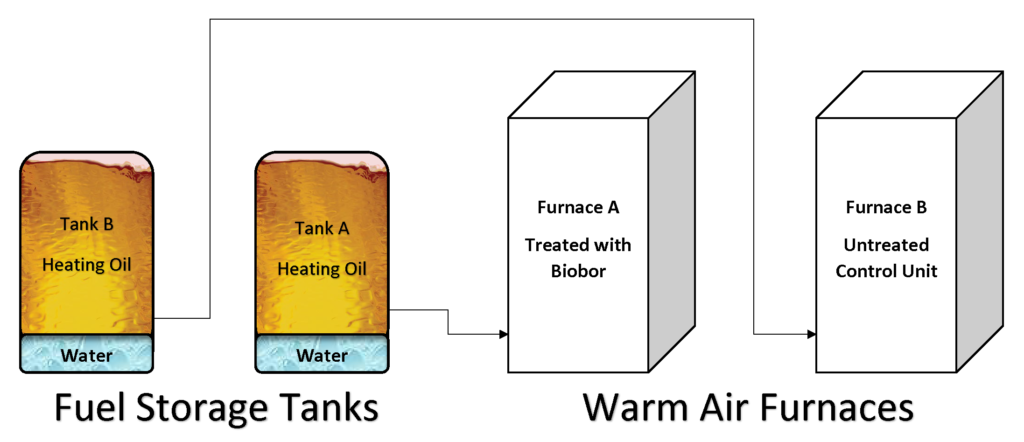

In one study, two forced air, oil fired furnaces were installed in the laboratory. The furnace nozzles were designed to burn 1.1 gallons of fuel per hour. The operating cycle of the burners was twenty minutes on and ten minutes off. This cycle was repeated until 1,200 gallons of #2 fuel oil had been consumed by each furnace. Both furnaces were equipped with their own 275 gallon storage tank. A high water bottom of ten gallons was added to each tank – the equivalent of over 13% water to fuel volume – to simulate what was being found in the field. The water supplied was taken from contaminated heating oil tanks in the Cleveland, Ohio area.

At the start of the study, the microbial contamination in each tank was identical at 500,000 colonies per ml in the water phase. The fuel phase contamination was too low to detect. A shock dose of Biobor was initially added to Tank A. Subsequent fuelings received a maintenance dose of Biobor. The treatments sterilized Tank A and kept it microbial free through the study.

The control unit, Tank B, did not receive any biocide treatment throughout the study. Over a period of 3 months the contamination level in the water bottom remained constant. However, the microbial contamination in the fuel grew as bacteria and fungi began to thrive at a significant rate in the untreated fuel.

Nozzle performance was analyzed for both Furnace A and B. The nozzles from the treated Furnace A fuel performed well showing no blockages or reductions in efficiency. In contrast, as the fuel in Tank B became contaminated, nozzles began to clog. The microbial contamination in Tank B caused nozzle clogging requiring service every 5-10 days of operation. The result of using Biobor in Tank A enhanced nozzle performance. This simulation of a typical home heating furnace operation, shows the advantage to using Biobor in every drop of fuel. Compared to Furnace B, it was evident it reduced maintenance and furnace efficiency of the Biobor treated Furnace A throughout the study.

Field Studies

Microbial contamination seriously reduces the storage stability of heating oil. Season to season storage of fuel is often accompanied by increased furnace maintenance due to the formation of insoluble gums. The production of insoluble gums increases with the presence of microbial contamination. To demonstrate this, four 150,000 gallon storage tanks were filled with #2 heating oil and 500 gallons of microbially contaminated water. Two of the tanks were treated with Biobor and two left untreated. Bacteria and fungi thrived in the untreated tanks, while the treated tanks were essentially sterile. Testing for storage stability was documented to determine the formation of insoluble gum over time. Two different tests were completed. The results are shown below.

Test 1 Results

The first test consisted of taking fuel samples from the 4 different tanks and storing them at 110°F with iron and copper catalyst coils. After one, two, three and four months storage the fuels were examined for insoluble gums. Four months’ storage under these conditions simulates over one year’s storage under normal conditions. The results of the analysis, as shown in Table 1, indicate that Biobor minimized the formation of insoluble gums by as much as 40% on average when compared to untreated samples.

| Storage Time | Tank A No Additive | Tank B No Additive | Tank C With Biobor | Tank D With Biobor |

| Initial | 1.0 | 0.7 | 0.9 | 0.9 |

| 1 Month | 1.7 | 1.0 | 1.3 | 1.3 |

| 2 Months | 7.7 | 6.7 | 2.8 | 1.7 |

| 3 Months | 14.6 | 14.2 | 5.3 | 8.1 |

| 4 Months | 15.3 | 18.2 | 11.7 | 10.9 |

Test 2 Results

After eleven months of storage in the four 150,000 gallon tanks, one fuel sample was taken from Tank B and one from Tank D. Each of the samples were tested for sediment (mg/1,000 ml) and microbial contamination. The test results, shown in Table 2 below shows how Biobor reduced sediment by over 37% and effectively sterilized the treated tank.

| Tank B | Tank D | |

| Biobor Added to Tank | 0 | 270 ppmW |

| Sediment, mg/1,000ml | 10.5 | 6.6 |

| Microorganisms in Fuel per mil. | 194 | 0 |

| Microorganisms in Water per mil. | 1,360,000 | 0 |

Customer Reviews

Studies and tests confirm the effectiveness of Biobor JF. So do our customer reviews. They are a good way to judge Biobor’s performance in the field. Considering Biobor JF has been on the market continually since 1965, there are certainly a lot of customer reviews to draw from. Here are a few off Amazon.

From mdshane

Works Great! Saved me money! I used this to treat a tank of #2 home heating oil to be sure there was no water related issues from storage – works great!

Mike Upstate NY

Always add this before storing the boat and beginning of heating season at home.

William Hildreth

Good product for killing bacteria and fungus in heating oil and kerosene tanks. Works fast and easy.

Jim

This is a great product to keep the slime/microbial growth out of the fuel. I have not had a clogged filter since using this fuel treatment.

Kodiak

Best biocide for the money. Have not had any more fuel issues, since I used this product. Tried another brand that didn’t work.

Christopher Marin

Bye bye bacteria. Hello clean diesel. AMAZING first time use put out 110% results!

All the Fuel, All the Time®

Biobor is the premiere fuel additive for jet fuel, diesel and gasoline

Share the Post