Five Main Causes of Blocked Filters

Studies consistently show that approximately 90% of diesel engine problems arise from fuel filter blockage. But what causes the blockage? Five main causes are identified along with helpful preventative measures for each.

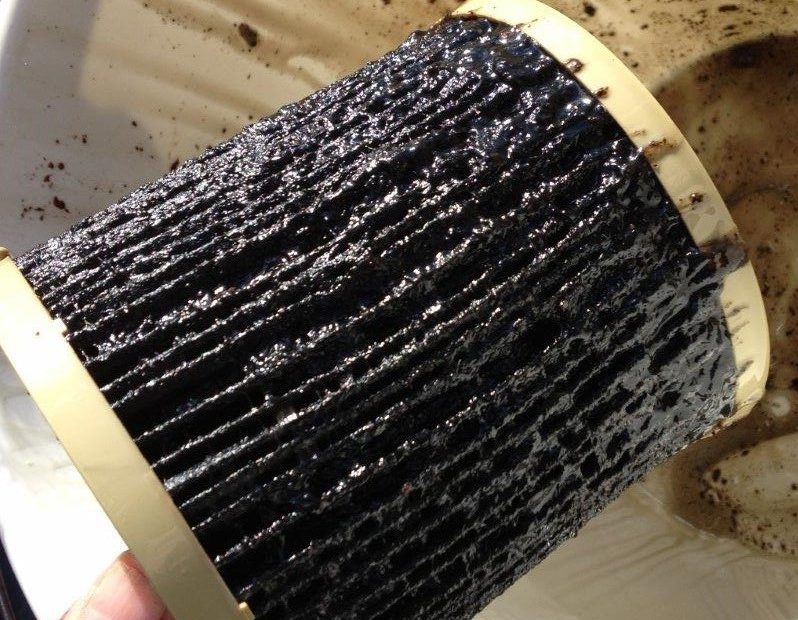

Contamination accumulates in the bottom of tanks. Water, rust and dirt enters the fuel tank and settles over. This collection of contamination will eventually reach a level that causes serious problems. Each time the fuel tank is filled, contamination is stirred into the fuel, becoming suspended. The suspended particles reduce filter life and cause increased fuel system maintenance costs. Whether in a vehicle or a storage tank, the action is the same. As time goes by, more frequent filter changes are required and higher maintenance costs are incurred. Periodic dewatering and tank cleaning can alleviate the majority of contamination problems.

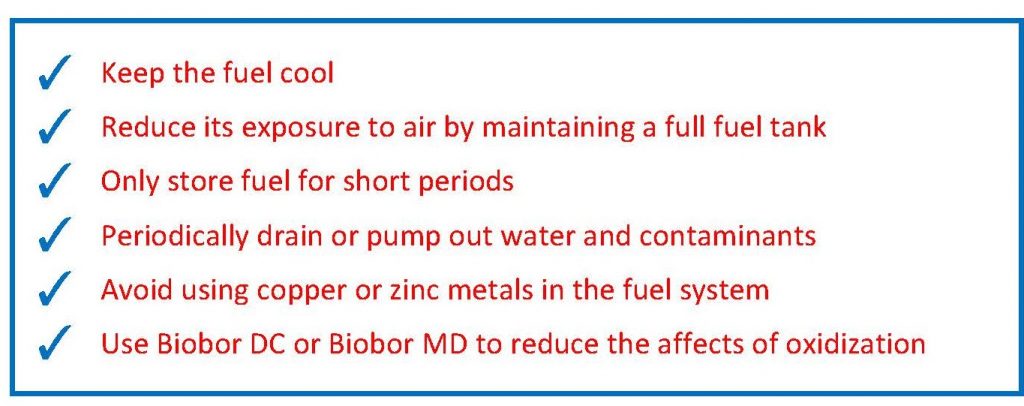

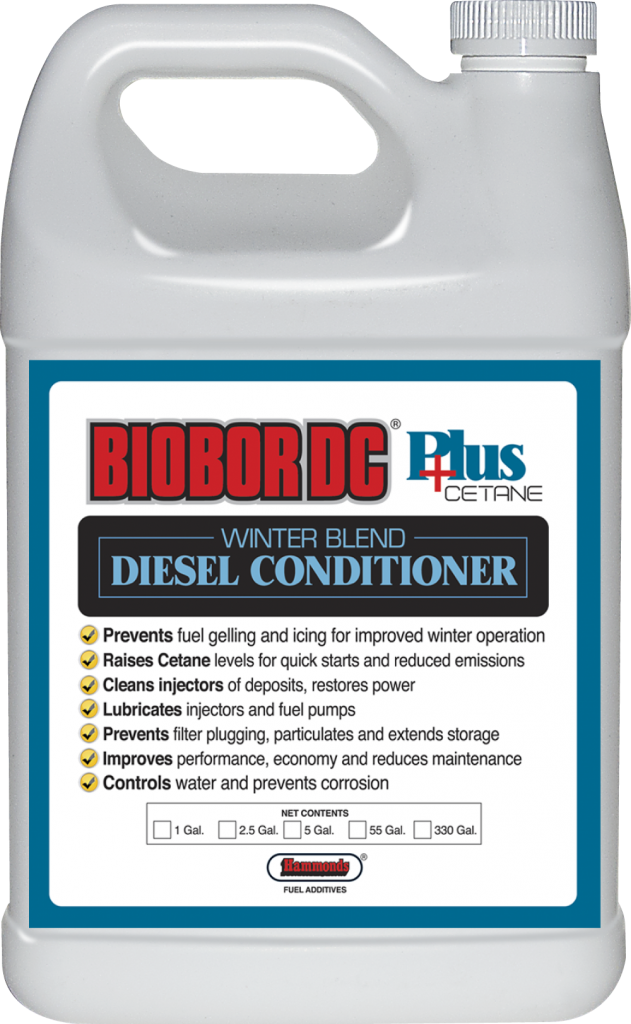

Oxidation occurs naturally with all fuels. When fuel is exposed to oxygen, it will oxidize (react with the oxygen) over time. Fuel turns dark and forms dark, sticky deposits that settle to the bottom of the tank. Oxidization begins immediately but generally takes some time to seriously affect the fuel. Two factors that seriously influence the speed of oxidization are temperature and water. The higher the temperature, the faster the oxidization. The more water present in the fuel system, the faster the oxidization. Oxidization increases filter blockages as well as engine combustion problems. Engines do not run well on highly oxidized fuel. The process can be minimized if you:

Microbial Contamination is a fact. Microbes are everywhere including your fuel system. The biggest contributor to microbial contamination is water. Like microbes, water is always present. Minimizing water accumulation will help, but will not prevent microbial contamination. Microbes produce acids and slimy biomass, blocking filters and destroying fuel system components. The best preventative is the regular or periodic use of a fuel biocide. A quality, fuel soluble biocide like Biobor JF is the only way to kill microbial growth and the most economical way to stop the problem before it starts.

Poor Aftermarket Additives can actually lead to filter blockage and engine problems. There are several factors to consider when using fuel additives. Laboratory testing and field experience confirm that Biobor Fuel Additives don’t contribute to filter blockage or engine problems related to fuel incompatibility. Biobor products are OEM approved so you can rest assured that you are getting the best!

Gelling is a temperature related problem. Diesel fuel contains paraffin wax. Under normal operating conditions, the wax remains a liquid and does not clog filters or harm the fuel system. However, when temperatures drop low enough, the wax crystalizes. Gelling starts at a certain temperature, called cloud point. The cloud point for diesel is approximately 14° F. If cold temperatures are expected, a good rule of thumb is to add an anti-gel additive at 15 degrees above cloud point. Biobor ColdFlo with Lubribor is an excellent additive or Biobor DC+Cetane Winter blend which will prevent gelling, stabilize the fuel and increase engine efficiency.

Check out all of the Biobor products to determine the best fit for your need.

Share the Post

Can I use automatic transmission fluid in diesel. As an additive.

While some have used ATF, it is not a recommended fuel additive. Choosing a quality, multi-functional diesel fuel additive is the best option. We recommend using Biobor DC+Cetane. https://www.biobor.com/products/biobor-dc-plus-cetane/

Thanks for the information.

You are welcome.