Reprint from Great Lakes Scuttlebutt, Published June 2015

Not Another Ethanol Article – The Additional Benefits of Marine Fuel Additives

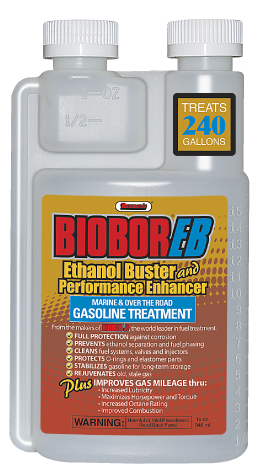

Since the introduction of ‘environmentally friendly’, enriched marine gasoline, ethanol and the severe issues that it can cause boaters and their engines have been hot topics in the boating community. Awareness and education of these harmful effects is an integral role of the marine industry, helping to reduce the headaches caused by these issues and maximize the time spent enjoying the water. A vital component to the ethanol solution is the consistent use of a well-balanced, properly formulated ethanol treatment produced by a reputable company. This includes a focus on the prevention of phase separation by controlling water and an industry proven corrosion inhibitor. However, ethanol treatments such as Biobor EB provide many additional benefits to a marine engine that are equally important.

All gasoline engines, including automobiles, will develop power-robbing carbon deposits over time as a result of the gasoline combustion process. Moreover, marine engines run at significantly higher RPM’s for considerably longer time periods resulting in the buildup of these deposits much more rapidly. Carbon deposits and varnish contribute to a few different engine issues, including poor performance and acceleration, difficult starting, increased fuel consumption and poor idling. “Biobor EB contains an industry proven detergent package that will remove existing carbon deposits and prevent future deposits on valves and injectors,” says Blake Rampy of Hammonds Fuel Additives. “The cleaning action of Biobor EB® ensures boaters that their marine engine will run smoothly and maximize the fuel economy of their vessel. Maintaining a clean fuel system is a primary contributor to a healthy, reliable engine when using ethanol blended fuels or conventional gasoline.”

An additional benefit of using a comprehensive gasoline treatment is maintaining fuel stability and quality. Unfortunately, marine fuel is not always turned over as often as desired and may remain stagnant for extended periods of time. A vessel’s fuel system is vented to the humid marine atmosphere, exposing the fuel to conditions unfaced by automobiles. While this is not only a contributing factor to moisture accumulation, combined with extended layup periods fuel can quickly degrade and breakdown from the moment it leaves the refinery. Stabilizers built in to a gasoline treatment can greatly extend the life and quality of gasoline and will prevent the thermal and oxidative breakdown of the fuel. “Biobor EB contains an industry-leading stabilizing package that will ensure boaters their fuel will remain on-spec and prevent the formation of gums and varnish for up to 18 months” comments Rampy. “This is especially important in the marine environment when fuel may begin to degrade even during brief layup periods.” Stabilizers are not just for winterizing, and in conjunction with a water and corrosion inhibitor are vital for ethanol and non-ethanol gasoline use.

As important as it is for the marine gasoline consumer to proactively protect their investment from the harmful effects of ethanol fuels, the use of a comprehensive fuel treatment designed to face all of these issues, such as Biobor EB, is essential. Biobor EB not only protects your vessel’s fuel quality, but ensures your boat will perform reliably each time you are out on the water.

Share the Post