The Negative Effects of Heat on Diesel Fuel

With the hottest weather on record this year, the heat is taking its toll on both humans and equipment. Diesel users typically know how to make their diesel engines run efficiently during the winter months, but this heat is something else. Record heat indexes have been recorded into the triple digits. Diesel fuel properties can significantly change due to heat exposure. How does that affect diesel fuel? What can be done to combat heat’s effect?

Five Ways Heat Affects Diesel Fuel

- Decreases Fuel Viscosity

- Decreases Fuel Density

- Increases Fuel Oxidation

- Increases Fuel Degradation

- Increases Microbial Growth

Viscosity

What is viscosity? Why does it matter if it decreases? Viscosity is defined as a fluid’s resistance to flow. Diesel fuel with too high a viscosity will increase engine operating pressures potentially resulting in abnormal engine wear and damage. Lowering viscosity results in reduced lubrication and abnormal changes in fuel delivery rate.

- Loss of lubrication relates to high engine wear. Lowering the viscosity of diesel fuel can cause accelerated engine component failures.

- Changes in fuel delivery rate has to do with the rate of injection and atomization of fuel during the combustion process. Any changes in the amount of fuel during combustion will reduce the engines efficiency and power.

Density

Diesel density relates to the amount of energy stored in the fuel molecule. The lower the density, the lower the energy output. Like cetane, fuel density is an important factor for proper engine combustion. What happens when fuel density is lower?

- Lower density will result in higher fuel consumption. So the engine is less efficient.

- Lower density can cause engine knocking resulting in engine damage if not corrected.

- Lower density results in less power. For large engines, this can pose a problem if power requirements are high.

Oxidation

Diesel fuel only has a shelf-life of around 6 months. Fuel oxidation is a natural part of fuel aging. It happens when fuel is exposed to oxygen. Heat is one factor that increases oxidation. Another is water. Often both combine to cause fuel to destabilize quickly. While fuel oxidation naturally occurs, the extreme heat of this season is causing major problems with stored diesel fuel. The more heat (and water), the less stable the fuel becomes.

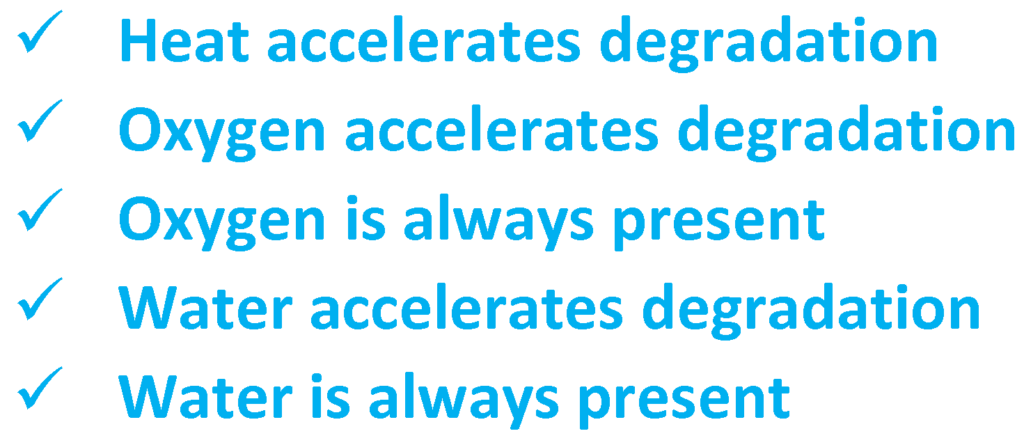

Degradation

Fuel degradation happens over time. When exposed to heat, the fuel begins to fall apart. The accelerated formation of gums, asphaltenes and sludge are all associated with heat exposure. The image shows how bad heat can degrade diesel fuel over a very short period of time.

Microbial Contamination

While there are microbes that grow in very extreme climates, most grow optimally at temperatures between 41 and 135 degrees F. Generally speaking, the higher the temperature in that range, the higher the rate of growth. As the outside temperature goes up and the temperature of diesel fuel with it, the more opportunity to see exponentially higher levels of microbial contamination. This is especially true with above ground storage tanks. Any daily vacillations in temperature (most common from night to day) can create the added effect of condensation. Water plus heat is always a bad combination as both support accelerated microbial growth.

What can be done to combat heat’s effect?

Some of the more obvious things to do is provide proper storage, handling and maintenance of fuel and fuel related equipment. Water management is an absolute necessity. Keeping fuel clean and dry will help to extend the life of your fuel, but good housekeeping is only part of the answer.

The addition of fuel additives to compensate for the effects of high heat are a simple and cost savings answer. Without them, the increased cost of maintenance and potential for engine damage or fuel loss is almost certain. So what do I need to use? Hammonds Fuel Additives manufacturers two products that can help stave off the serious complications caused by heat.

Share the Post