Morpholine Biocides

Part 3 of A Biocide Analysis examines NMEND biocides. They are also referred to as nitrobutylmorpholine or morpholine. NMEND was originated in 1972 and like almost every other fuel biocide, it is repackaged or relabeled under a variety of brand names and produced by only a few manufacturers.

Most Common NMEND Fuel Biocide Brands

- IFF Fuelsaver (Busan P-1487 – Original Product)

- Innospec Predator 6000 (repackage)

- Power Service Bio Kleen Diesel Fuel Biocide (repackage)

- Valvtect Bioguard ULS Biocide (repackage)

- Certified Labs Tank Tonic (repackage)

Once again, we will be using the same 6 attributes we have used in the last two posts: solubility, potency, compatibility, acceptability, stability and handleability.

SOLUBILITY

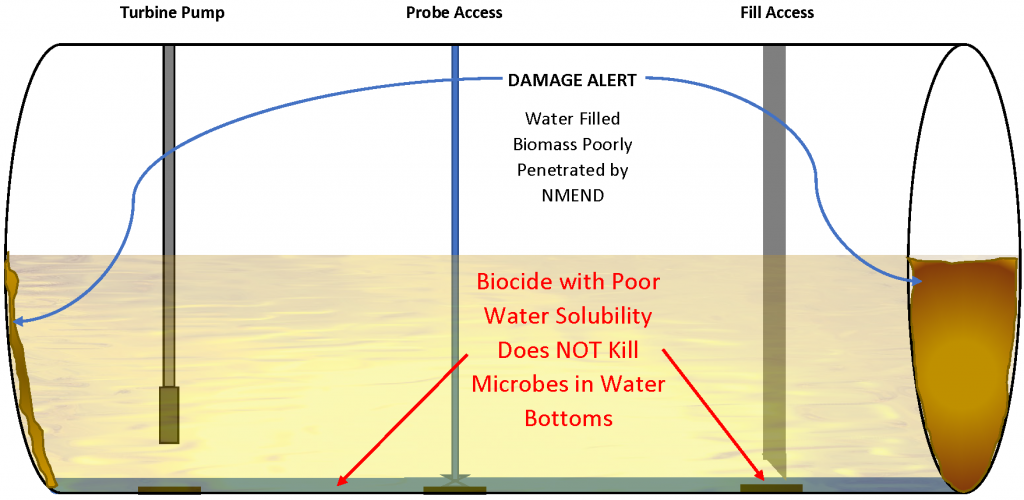

An ideal biocide must be a true dual phase biocide, possessing good fuel and water solubility. It must first be able to solubilize (stay in solution) in the fuel then be able to properly partition into water. The last two biocides we investigated had very poor fuel solubility. Much of the NMEND product literature claims it is a dual phase biocide. While NMEND is fuel soluble, studies show it to be only 1% water soluble, virtually insoluble in water where a majority of microbial contamination is found. In order for a fuel biocide to be effective, it must have adequate water solubility. If it cannot partition into the water, where the largest percentage of microbial contaminants live, then it will not provide acceptable protection to the fuel system.

Because of its poor water solubility, it has been suggested in one study that NMEND be injected through a tanks bottom drain valve in an effort to force it into the water phase. One problem is most tanks do not have bottom drains, certainly not underground storage tanks. There is no effective way to properly treat the water phase when using NMEND.

POTENCY

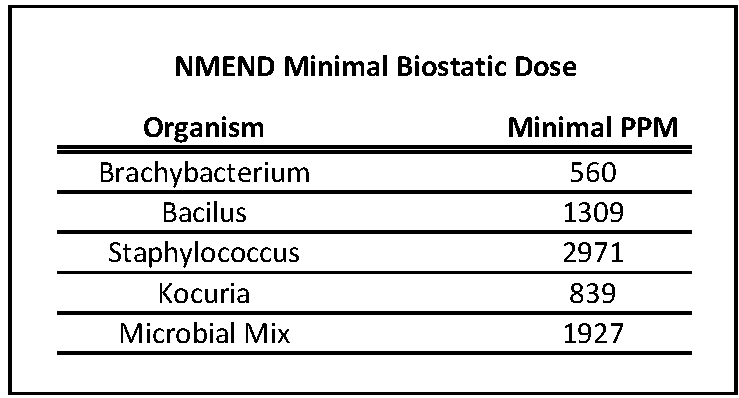

The ideal fuel biocide will be able to provide a cost effective, broad spectrum kill. In many studies and the manufacturer’s own literature, it was found that it can take almost 3000 ppm to inhibit growth of some microbial species. That is more than 3 times the manufacturer’s recommended allowable dose of 1,000 ppm. Results shown in the chart reveal some common microorganisms tested.

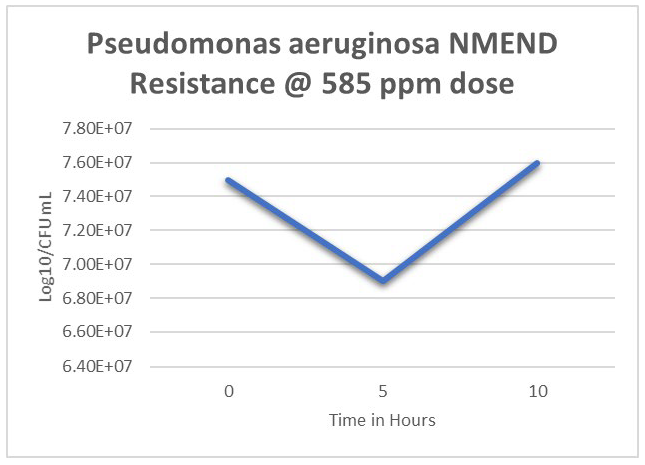

Other tests show additional organisms with similar results. Shown is the minimal biostatic dose required. Biostatic is a sublethal dose, intended to reduce microbial reproduction. It should not be confused with a biocidal or kill dose. Microbes will still multiply. One of the concerns associated with a sublethal dose is adaptation or biocide resistance. The graph shows the results from a study on NMEND resistance. One of the more common microbes found in fuel is Pseudomonas aeruginosa.

The study found that the microbe was resistant to a shock dose at 585 ppm of NMEND. An ideal fuel biocide should not be vulnerable to adaptation or resistance. The graph clearly shows that the biocide was not able to make an effective kill or reduce the microbe population. The bacteria continued to multiply. Observations in other studies show that NMEND is not effective against any microbial contamination in diesel fuel.

When compared to the data, manufacturer and individual branded product claims are all overstated. The published maintenance dose of 142 ppm, the shock dose of 390 ppm nor the maximum allowable dose of 1,000 ppm is enough to make an efficacious kill. Because it can take upwards of 3,000 ppm or NMEND to eliminate an organism, the dose limitations and recommendations are ineffective. Anything less than a lethal dose can result in adaptation as shown above. In contrast, Biobor JF results show effective kills on all organisms tested even at lower dose rates. According to the data, 3 gallons of biocide for every 2,500 gallons of fuel is required to be biocidal. The cost to administer NMEND at a very high kill dose is not the answer. Biobor JF only requires 200 ppm to be effective, NMEND requires 5 times that amount. This is not a cost effective answer.

COMPATIBILITY

Compatibility issues are not always evident. Although no fuel system material compatibility data is available for NMEND, there are some concerns with its fuel compatibility. Studies have shown that NMEND is not compatible with common diesel additive components. It has been postulated that NMEND reacts with the additives causing biocide deactivation. That may relate to other studies showing the biocide ineffective against microbial contaminants in diesel. No doubt that this is a concern for any users of the biocide, especially those using it to preserve diesel fuel in long-term storage.

ACCEPTABILITY

A biocides acceptability is important. One of the questions often asked, “Does the biocide contain any questionable substances?” In the case of NMEND, one of the ingredients is formaldehyde. It’s use may become restricted or unfavorable due to the formaldehyde content. The CDC identifies formaldehyde a systemic poison. We will talk more about its toxicity in a later section. Acceptability also has to do with the cost of using a product. When a less expensive option is available, why use NMEND. It has already been discussed how high doses are required in order to be effective. The higher dose raises the actual cost to treat fuel more than ten times higher than the effective Biobor JF dose. Questionable ingredients and high costs affect NMEND’s acceptability.

STABILITY

NMEND is affected by pH, temperature and fuel stabilizer additives. The manufacturer’s label warns against exposure to a pH lower than 6. The possibility of microbial acids pushing the fuel pH below 6 is real. At this point, NMEND destabilizes and becomes ineffective.

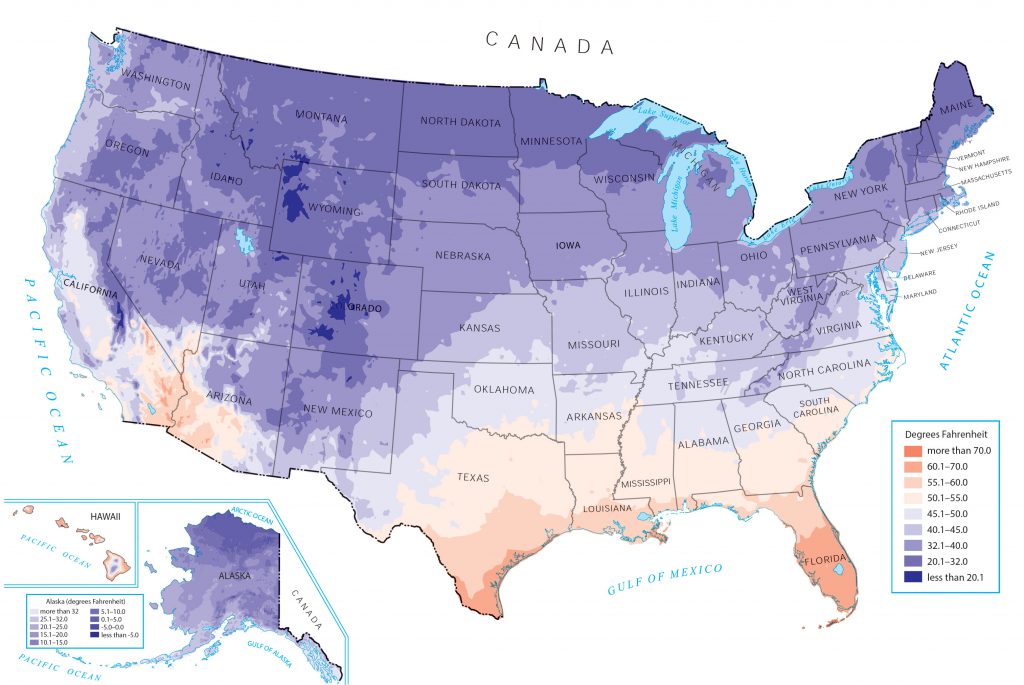

Temperature is also a major concern with NMEND. According to product literature, it freezes at 50.9° F. In the map below, you can see how a 50° F freeze point would create a real problem with applying the product and a potential stability problem once it is applied to fuel. So many areas where there product would be frozen solid and unusable.

Take a look at a product sample at its freeze point.

The original manufacturer’s warning says it all:

“FUELSAVER can be shipped and stored at normal ambient temperature (above 50°F/10°C) without phase change. At lower temperatures, crystallization in the product may occur because of extreme cooling. Should this occur, the product may be liquified by immersing the drum in warm water or storing it in a heated area until the crystals thaw.”

Manufacturer’s Product Warning

As previously mentioned, the product is also known to deactivate by reaction with stability additives commonly found in fuel. Stability is of major importance. Biobor JF is both pH and temperature stable. In temperature testing, Biobor JF was allowed to cool to -105°F. While it was more viscous, it never froze. The exposure to extreme low temperatures had no detrimental effect to Biobor JF. This is a stark contrast to a product that solidifies at temperatures below 50°F. Not a good choice for most of the world’s applications.

HANDLEABILITY

Toxicity is a major concern for anyone handling a biocide. According to the manufacturer’s literature, NMEND is a toxic substance requiring the user to coverup and where goggles or a face shield. It is a known skin sensitizer, so if it splashes on the user, it must be removed immediately. Occupational exposure is a concern with this product. It has been verified that contact allergies to the biocide are common. NMEND is also very toxic to the environment, especially marine life. Extra care in using this biocide around water is advised. According to the literature, any release into the water will have a negative effect on marine life.

This is another biocide long on promise and short on delivery. It is only effective with very high doses. It may not be effective at all in diesel fuel with stability additives. It is susceptible to adaptation and known to be ineffective with common microbes found in fuel when treated at the recommended dose rate. The two most glaring negatives are its freeze point and the cost to apply the product. There really is no good reason to use any NMEND biocide. Use Biobor JF, the ideal fuel biocide instead. After 57 years, it is still the best solution for microbial contamination in all hydrocarbons.

Follow BioborShare the Post