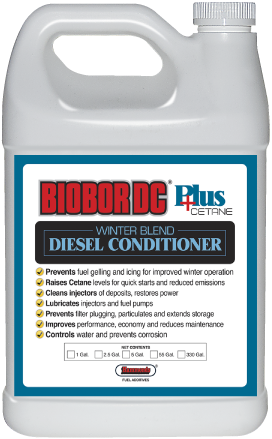

BioborDC + Cetane

Diesel Conditioner & Performance Additive

- Cleans up injectors and prevents deposits

- Extends fuel filter life

- Controls water and prevents corrosion

- Improves efficiency and restores power

- Lubricates injectors and fuel pumps

- Prevents fuel degradation and gumming

- Increases storage stability

Biobor®DC+Cetane is a multifunctional warm-weather diesel fuel conditioner designed to enhance the stability, operability and performance of ultra-low sulfur diesel fuel. The components of Biobor®DC+Cetane provides exceptional fuel stability, added lubricity, detergency and water/corrosion control. With continued use, Biobor®DC+Cetane enhances the performance and life of diesel fuel while protecting and cleaning vital engine components, maintaining fuel economy and reducing emissions. Biobor®DC+Cetane is a cost effective diesel treatment for large users providing complete protection at concentrated treat rates.

Available in: 1 Gallon (4 per case), 2.5 Gallon (2 per case), 5 Gallon, 55 Gallon Drum, 330 Gallon Tote

Remove any water or contamination present in the fuel prior to applying additive. For seriously contaminated systems, consider fuel and tank cleaning. Use Biobor JF with Biobor DC to kill and prevent further microbial contamination, when present. There are three methods of applying an additive.

- Metered Injection - Hammonds Technical Services offers fluid powered injector systems designed to automatically inject and blend the additive thoroughly as fuel passes through the system. Metered injection is the most accurate and effective method for applying an additive. Interested in learning more, use our contact form and let us know.

- Splash Blending with Circulation - Adding the additive during filtration is an effective way to blend the additive quickly and effectively. If you plan to clean your fuel and tank, splash blend the additive in at the end of the filtration process to allow the additive time to mix.

- Splash blending during Fueling - The most common way to blend the additive is during a fueling event. Simply add the additive prior to fueling and the agitation provided during the fueling event will provide enough blending action to properly mix the additive.

Biobor DC+Cetane Summer Resources

SDS

Spec Sheet

Product Literature

Related Industries

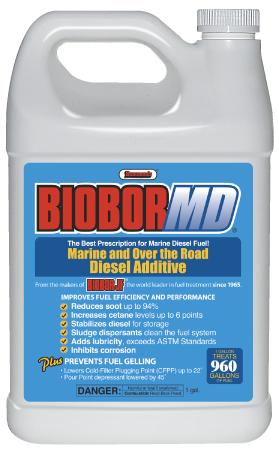

YEAR-ROUND FUEL PROTECTION

Make sure your engine runs at peak performance by using one of Biobor’s fuel additives designed for every season and every situation.

- Kills and prevents microbial growth

- Dual phase – works in both fuel and water

- Increases lubricity

- Prevents corrosion in fuel systems

- Recommended by OEMS worldwide

- Prevents clogged filters

- The industry standard since 1965

All the Fuel, All the Time®

Biobor is the premiere fuel additive for jet fuel, diesel and gasoline