When it comes to cleaning heavily contaminated fuel tanks and treating contaminated fuel, the task can be daunting. Microbial contamination in a fuel system can cause a range of issues, from corrosion to equipment failure, and tackling it requires an effective, multi-stepped approach. In this blog post, we will take a look at the steps involved in dealing with heavy microbial contamination in fuel systems.

What is Microbial Contamination?

Unchecked fuel systems can incur serious damage due to microbial contamination, leading to product loss, liability increases, and Microbial Influenced Corrosion (MIC). Commonly found organisms in fuel are bacteria and fungi, but it is important to note that no single microbe causes the problems associated with fuel contamination and fuel system damage. There are two main types of microbes present in fuel systems: planktonic and sessile. Planktonic microbes are suspended in the fluid and are more easily controlled than sessile microbes which form biofilms.

It is vital to understand that microbes work in consortia and biodeterioration results from microbes working together. Biofilms form as planktonic microbes attach themselves to a surface and secrete a slimy substance that encapsulates the microbes. This slimy substance can provide microbial communities protection from biocide treatments. Also note that biofilms can form and are often found suspended in the fuel. The composition of the microbial population profile is determined by several factors including water contamination, particulate contamination, and pH.

There are two commonly found microbial population profiles present in fuel systems, dominant and subordinate microbes. Dominant microbes grow faster and subordinate slower. Because dominant microbes have higher metabolic rates, they will tend to absorb a biocide quicker than subordinate ones. As a result, it is not uncommon to see an immediate kill, then a subsequent increase in microbial activity in heavily contaminated systems. This happens when the dominant species die and the subordinate ones take over. The biocide is spent on the dominant species, the reason why heavily contaminated systems often require more than one biocide treatment. Having a basic understanding of fuel microbiology is important in order to properly assess microbial contamination. This understanding should include knowledge of microbial testing and biocide use.

The Consequences of Microbial Contamination

Microbial contamination in your tank directly relates to problems throughout the entire fuel system. MIC is the most prevalent consequence of microbial contamination and is responsible for a host of related issues. If MIC is not identified, microbes will cause a myriad of operational issues including:

- Premature dispenser filter replacement

- Corroded dispenser filters

- Dispenser meter corrosion

- Corroded STP components

- Frequent or repeated proportional valve replacements

- Slow-flow dispenser issues

- Premature or frequent dispenser hanging hardware failure

- Leak detector failure

- Shear valve failure

- Line and tank failure

- Probe malfunctions and failures

- Water probe false readings

- Site downtime

- Loss of business

The Multi-Step Approach to Removing Microbial Contamination

When dealing with microbial contamination in a fuel system, it is important to take a multi-stepped approach to ensure the best outcome. This approach typically includes treating the problems, cleaning the tank and implementing a fuel quality management (FQM) program to alleviate future issues.

1. Treat the Problem

The first step to removing microbial contamination is to treat the problem. Apply a shock dose of Biobor JF and allow it to soak. It is important to note that biocides are only effective if they are used at the recommended dosage, adequately blending and left in the fuel system for the appropriate amount of time. The best way to ensure its optimal effectiveness is by properly blending the biocide with fuel. This can be accomplished by using a pump to recirculate the biocide in the fuel. A biocide can also be added during a fuel drop. When using Biobor JF, this will provide enough agitation to effectively blend the biocide into the fuel. Since the dry space above the fuel can be contaminated, it is helpful to fill the tank as full as possible so that the biocide reaches all affected surfaces. One of the major advantages of Biobor JF is its high fuel solubility. In the absence of adequate mixing, it will solubilize evenly throughout the fuel. Other biocides will not.

2. Clean the Fuel and Tank

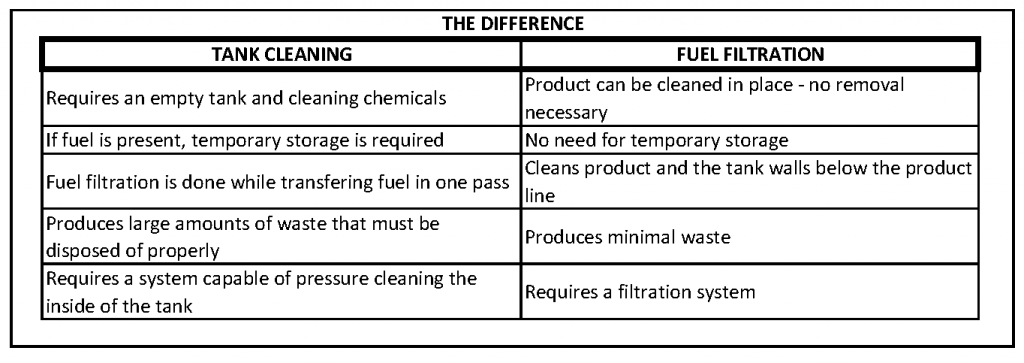

The second step in removing microbial contamination from a fuel system is to physically clean the fuel and tank. Removing dead microbes, biomass, particulate contamination and water is essential. Fuel cleaning or polishing may do the job, but if heavy biomass is present it might require jetted cleaning. That means removing the fuel and using a pressurized jet to clean the tank surface. While tank cleaning and fuel filtration are two different approaches, they both work to reduce the level of contamination.

Once cleaning is complete, add another shock dose of Biobor JF to the fuel. Heavily contaminated systems often require more than one biocide treatment to ensure recontamination does not occur. This can be done during the final stages of fuel filtration to ensure adequate mixing. It is important to note that biocides are only effective if they are adequately mixed, used at the recommended dosage and left in the fuel system for the appropriate amount of time.

3. Implement Hammond’s Test, Treat, Protect (TTP) program to manage your fuel system. Developed to help fuel system owners and operators manage fuel quality, TTP is a simple program that will help you reduce the problems so common with fuel today. Want to know how to get started with TTP? Contact Hammonds.

Share the Post