Diesel Fuel Quality

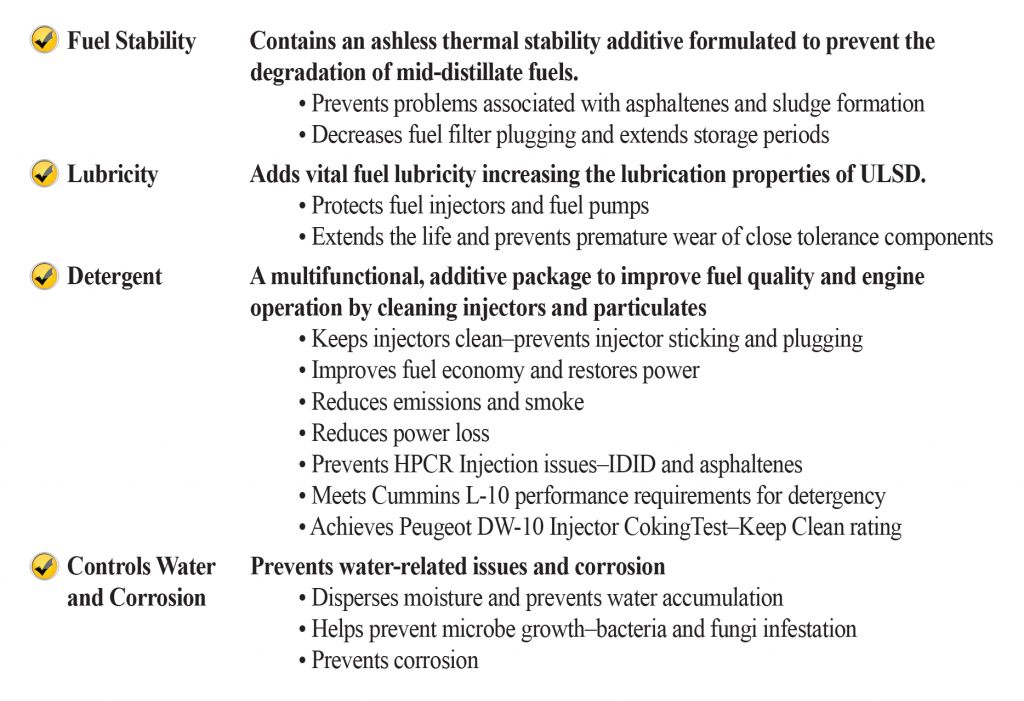

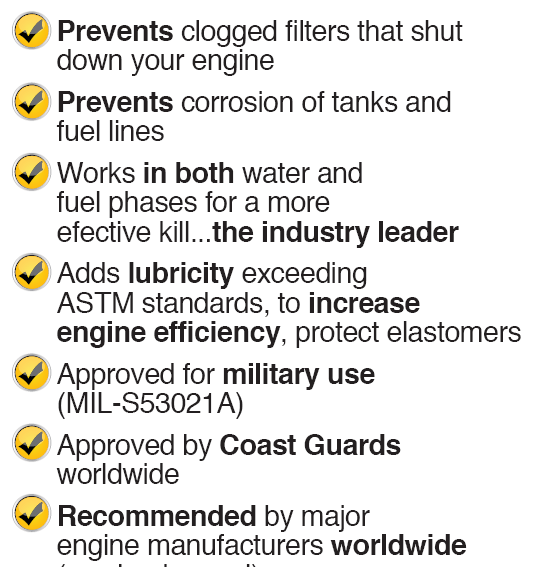

Fuel quality is something that has to be taken seriously. It has been estimated that around 70% of diesel engine failures are due to poor fuel quality. Over the last five posts, we have discussed how different fuel additive components can essentially improve and preserve fuel quality. In this post we will bring it all together and wrap things up. It is hard to underestimate the role fuel additives play in reducing maintenance costs and downtime. For the diesel engine owner, two areas of significance deserve repeating. Both the reduction of microbial contamination in fuel and the total fuel quality are an imperative. Two products that address these, Biobor JF and Biobor DC+Cetane.

Along with the proper use of additives, fuel quality management practices must include the following:

- Remove water. Check your tanks monthly and remove any water found.

- For long-term and seasonal storage, keep you tank topped off. A full tank will reduce the possibility of water accumulation due to condensation.

- Take monthly bottom samples. If your fuel starts to darken, you have a problem somewhere.

- Test your fuel for microbial contamination. A better option is to use Biobor JF in every drop of fuel to preserve the fuel and reduce maintenance costs associated with microbial contamination. Remember, by using Biobor JF you are also adding lubricity. It’s not just a biocide!

- Clean your storage tanks once a year. Contamination accumulation is real. As your tank vents and breathes, it takes in contamination. This includes physical and biological contaminants.

Want to know more about how to save costs and prevent unnecessary downtime, contact us and ask us to send you a copy of our fuel quality management program. Just mention TEST, TREAT, PROTECT….

Follow BioborShare the Post