Imagine having almost ten gallons of contaminants in your fuel tank like the picture shown. The site owner had been replacing dispenser filters frequently and noticed higher maintenance costs on his fuel equipment. Imagine the surprise at what was found in the bottom of his tank. Once the tank was cleaning and Biobor®JF was used to kill microbial growth, his fuel maintenance costs dropped by almost 35%. He later confessed to having few customer complaints about his fuel. Dirty fuel and fuel tanks represent higher costs and liabilities. Dirty fuel is a fuel system killer!

While fuel contamination is a reality, the problems can be minimized with a fuel quality management plan that includes fuel sampling, fuel testing and fuel additives. We call it

Sample your fuel to determine visual clarity. If the fuel looks bad then it is bad. In the case of the contaminated fuel pictured, the fuel had become severely contaminated over a period of time. Fact, a tank that takes an 8,000 gallon delivery each week will accumulate around 30 pounds of solid contaminants each year. Add to that microbial contamination. In the case of this fuel system microbes were eating the fuel and leaving an acidic byproduct in the tank. The contaminants removed from the tank were part of a larger problem. The acids found in the bottom sample and mid-tank samples, a by-product of the microbial biodeterioration, were eating away at the fuel system components and clogging dispenser filters.

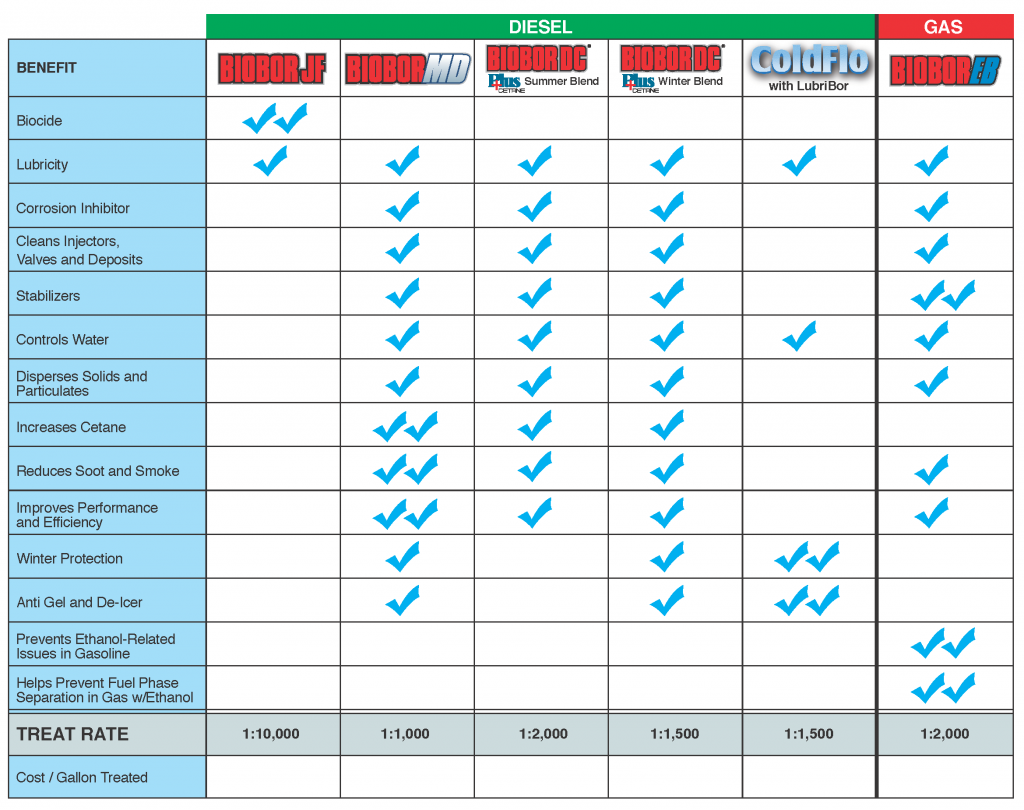

Once the fuel and system are cleaned, fuel additives help reduce costs and liabilities by breaking up and dissolving fuel sediment sludge. A fuel biocide kills the microbes that damage both the system and fuel. A fuel additive plan pays for itself by reducing costs, reducing liabilities and creating a point of differentiation between you and your competitors. Build your image and save costs by using Biobor® products today.

Share the Post