Recently the Nigerian Civil Aviation Authority issued an urgent safety warning to refuelers and operators concerning fuel contamination at three airports. The All Operators Letter released revealed over two months of likely contaminated fuel was being used. It disclosed serious water problems potentially associated with infrastructure and maintenance. Unfortunately, these problems are not single incidents. With the extreme weather events happening on a global scale, occurrences like these will become more frequent. Severe heat, temperature vacillations and water all contribute to the ongoing concerns with fuel contamination.

Three Common Contributors to Jet Fuel Contamination

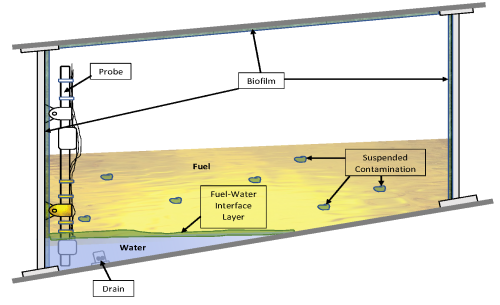

- Water – Water is everywhere and happens to be the most prevalent and potentially damaging contaminant in jet fuel. There are three forms of water common to fuel systems:

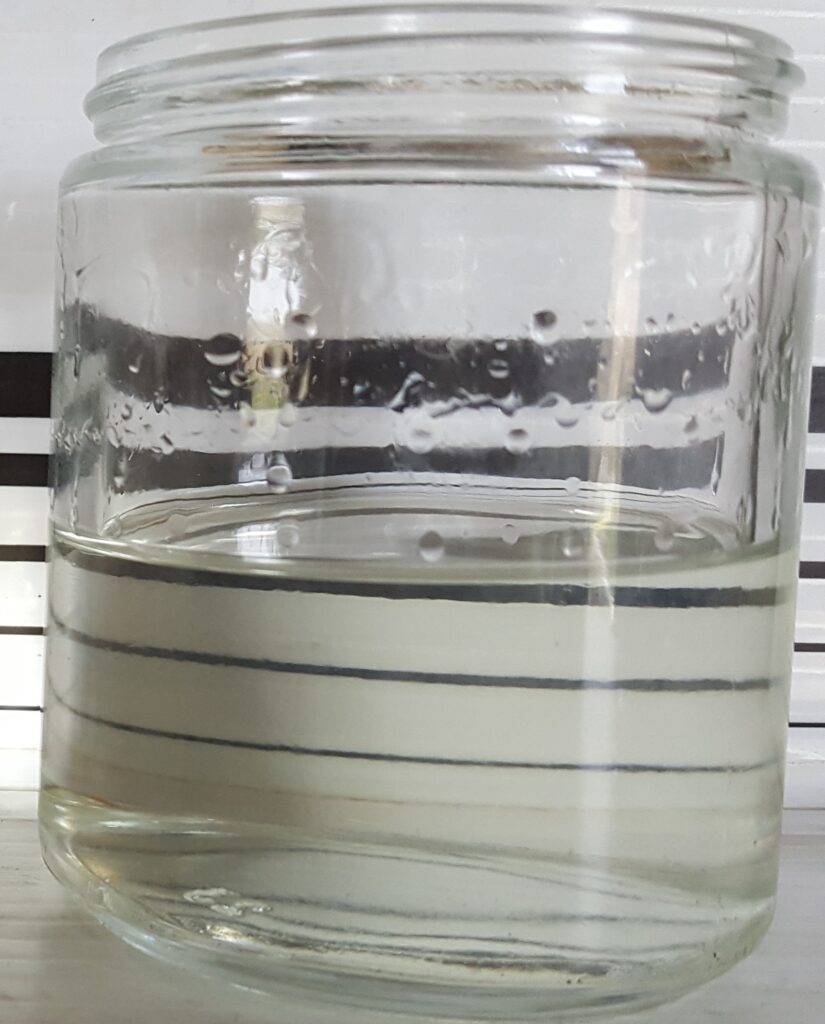

- Dissolved water in fuel appears clear.

- Dispersed water in fuel appears hazy.

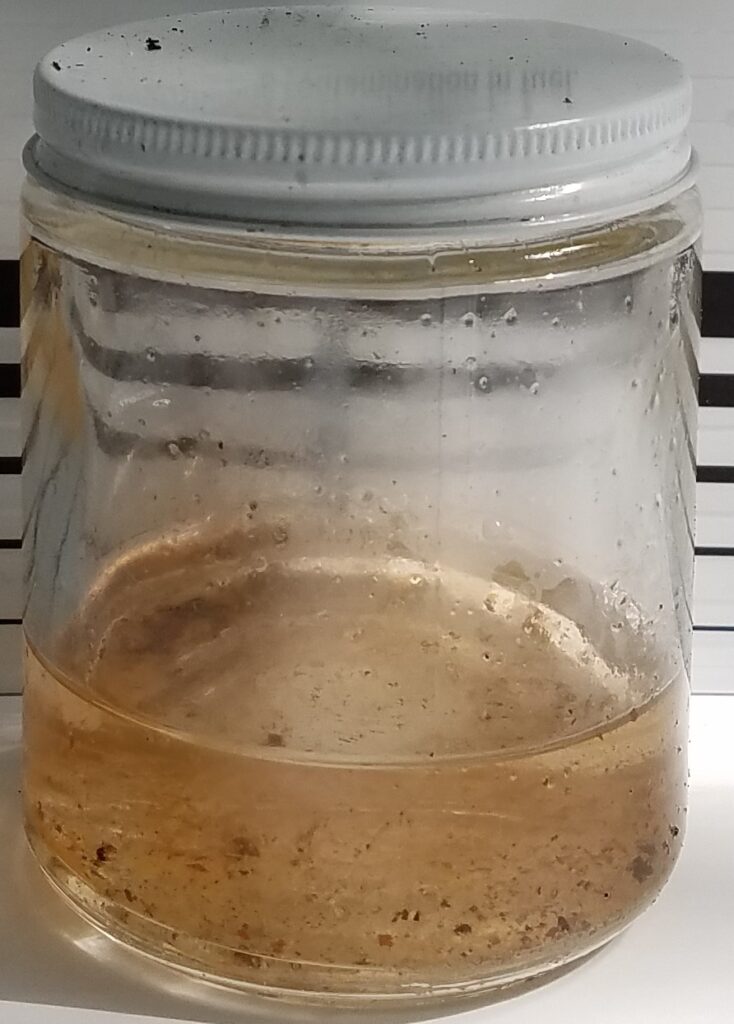

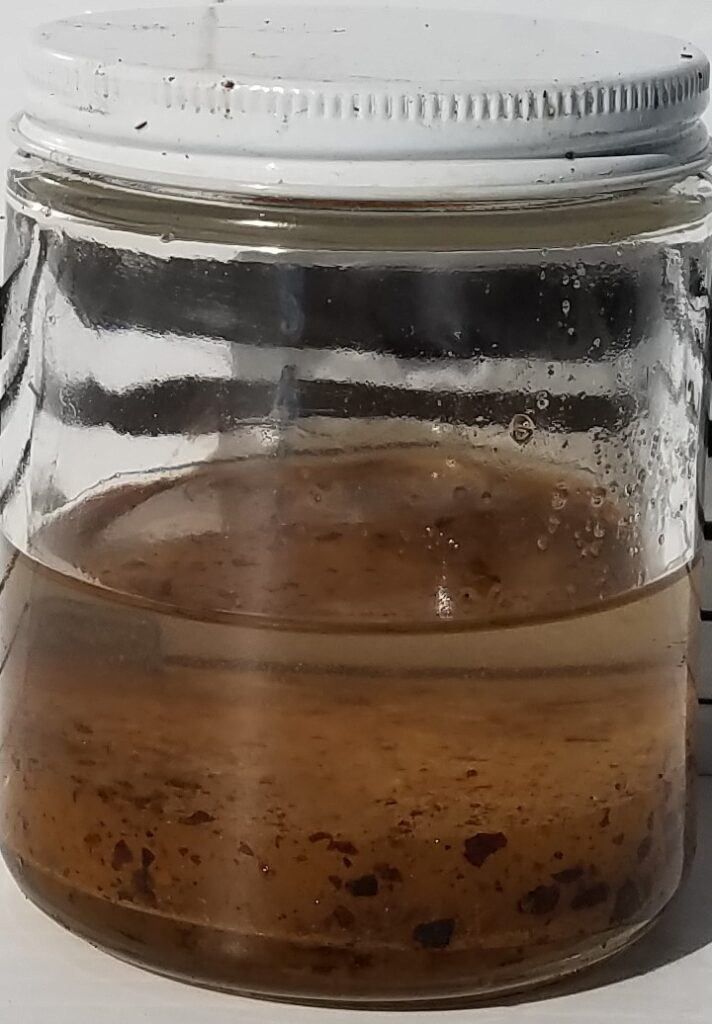

- Free water in fuel accumulates on tank bottoms, walls and found emulsified in fuel.

- Particulates – Particulates are also everywhere, often found as sediment and suspended in fuel. There are three major sources of particulate contamination often found in jet fuel:

- Foreign debris, including metal chips, coating materials and rubber components are common.

- Fine particulates like clay, rust or dirt and CMAS (calcium, magnesium and alumino-silicate) are found in jet fuel.

- Residuals and sludges in the form of degraded fuel components and biofilms are common in fuel stored for longer periods of time or when fuel is exposed to extreme weather events causing accelerated fuel degradation.

- Microbiological growth (MBG) – One of the most concerning contaminants in jet fuel is MBG. Responsible for operational problems, corrosion and flight safety, microbes are also everywhere. They are in the air we breath and in fuel systems. Two types of microbes are found, bacteria and fungi (includes molds and yeasts). Some require an oxygen environment to survive (aerobes) and some require an environment without oxygen (anaerobes), while others can live in both environments (facultative). Here are some interesting MBG factoids:

- It is estimated that the earth contains over 1 trillion different microbes.

- Around 1 billion species of microbes have been identified.

- Around 1,000 species are known to live in fuel systems.

- Around 100 species are known to cause serious fuel and fuel system damage.

Is there a way to circumvent fuel contamination issues?

The short answer is yes. Good housekeeping is essential to the solution. However, good housekeeping alone will not always keep you from having contamination issues. Hammond’s Test Treat Protect approach to fuel quality management is a good place to start.

If you want to know more about Hammond’s Test Treat Protect program, contact us.

Follow BioborShare the Post